Pressure transmitters

What are pressure transmitters?

Pressure transmitters are electronic pressure gauges and are used to measure and monitor pressure. The term pressure transmitter is also often used for pressure transducers or pressure sensors. However, this is not a synonym, since the term pressure sensor in the narrower sense only describes a part of the pressure transmitter.

They are available in many different designs to suit pressure and electrical connections, measuring procedures, electrical output signals and certifications (CE, EX, rail and ship). Superior technology and precise manufacturing ensure that the transmitters work perfectly. This is especially important in applications where high requirements are placed on long-term stability, vibration resistance, electromagnetic compatibility, shock resistance or temperature insensitivity.

What does a pressure transmitter consist of?

A pressure transmitter consists of a sensor that uses a physical principle to convert the pressure or a change in pressure into an electrical signal. In addition, a pressure transmitter contains measuring transducer electronics that process the sensor signal and convert it to a standardized electrical output signal. The output signal is provided at the electrical connection. The pressure on the sensor is applied via the pressure connection (also called the process connection). The sensor and electronics are housed in a housing that protects these two sensitive components from environmental influences on the one hand and connects them to the electrical connection and the pressure connection on the other.

What are the selection criteria for a pressure transmitter?

The selection criteria for a pressure transmitter are the appropriate measuring range, the required accuracy and the desired output signal. However, another very important criterion is the suitability of the pressure transmitter for the desired application. The measuring range, the accuracy and the output signal are parameters that are relatively easy to determine. On the other hand, in order to determine which type of pressure transmitter is suitable for a specific application, it is necessary to have a certain amount of experience and to carefully consider various aspects.

Are you looking for a suitable pressure transmitter for your application? Our experts in pressure measurement technology will be happy to advise you online or on-site. Please contact us.

Selection criteria for the ideal pressure transmitter in your application

Pressure type: In pressure measurement technology, a distinction is made between absolute pressure, relative pressure and differential pressure. Absolute pressure always refers to the absolute vacuum as the zero point. Relative pressure measurement is the measurement of the differential pressure between a medium and the ambient or atmospheric pressure (approx. 1bar). The following article explains the differences in detail.

Measuring range: This is the pressure range between the minimum pressure (at which the output signal outputs 0%) and the maximum pressure (at which the output signal outputs 100%). The difference between the minimum and maximum values is referred to as the span and serves as a reference for almost all accuracy specifications in pressure measurement technology. As a rule, the measuring range of pressure transmitters is standardized to a specific pressure measuring unit, e.g. bar, mbar or psi. In addition to the pure signal range, overpressure and burst pressure limits must also be taken into account. These are important in applications where pressure peaks – even very brief ones – can occur well above the measuring range.

Accuracy class: In practice, it has been shown that the definition of the required accuracy class or the permissible measurement uncertainty of the pressure gauge is a great challenge. On the one hand, the accuracy class includes various aspects or parameters of the measurement uncertainty, which does not have the same significance in most applications. On the other hand, it is also often difficult to determine how accurate the measurement actually needs to be on the application side. Higher accuracy almost always entails a massive impact on product cost. Therefore, it is important to weigh well what is mandatory when selecting the accuracy class.

Output signal: For the output signal, a distinction is made between three main categories: Unamplified sensor signal, analog (standard) signals and digital signals. The output of the unamplified sensor signal is very rarely desired for pressure gauges; this is in contrast to temperature gauges, which very often provide the signal of the PT100/PT1000 resistor directly without additional electronics. If the unamplified sensor signal is now output, the pressure measuring instrument is not a transmitter or measuring transducer in the narrower sense. Rather, it is then referred to as a measuring cell with a housing. These are often also called transducers. Analog signals are still the most widely used in pressure measurement technology in industry today, above all the current signal 4 ... 20mA. The advantage of analog signals is still the significantly lower costs for pressure transmitters and often also for the downstream evaluation electronics. However, the costs of digital transmitters and evaluation units have dropped significantly in recent years. In addition, the spread of sensor bus systems such as IO-Link or CANopen in pressure measurement is increasing rapidly. The main advantages of digital signals are the higher safety against errors, diagnostic and parameterization possibilities as well as the combination of several measurement parameters in one device, for example pressure and temperature. Electronic pressure switches are also counted among the pressure transmitters with digital signals.

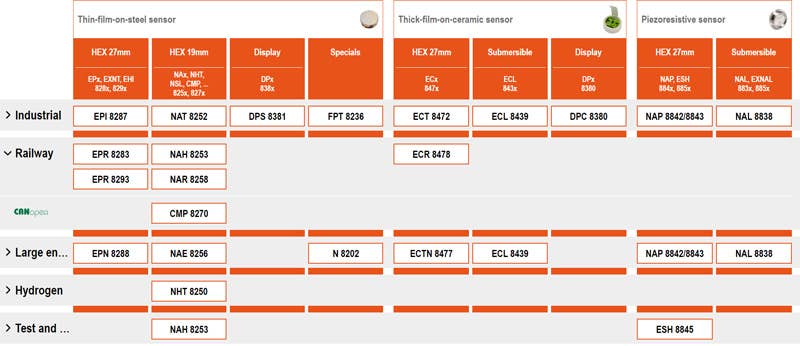

Sensor: The pressure sensor is the core element of the pressure gauge. In pressure transmitters, this pressure sensor is usually an element where a change in pressure leads to a deformation of the diaphragm. This in turn leads to a change in electrical resistance on specially applied resistive elements. The most commonly used sensor technologies are thin-film-on-steel, thick-film-on-ceramic and piezoresistive sensors. In thin-film-on-steel sensors, resistors are sputtered onto a stainless steel diaphragm. The main advantage of these pressure sensors is their excellent long-term stability and high robustness against pressure peaks and temperature influences, as well as pressure measurement over large pressure ranges from about 200mbar to over 3'000bar. Thick-film-on-ceramic sensors are based on a ceramic base body on which the resistance bridges are applied and then burned in. The ceramic membrane is considered to be extremely robust against almost all corrosive liquids and gases and is preferably used when aggressive chemicals have to be measured. The measuring ranges start at about 100mbar and go up to about 400bar. In piezoresistive pressure transducers, the resistance of silicon semiconductor elements changes with pressure. These semiconductor elements are isolated from the measured medium by an oil filling and a thin separating diaphragm. Due to the high sensitivity and the low hysteresis of the silicon element, piezoresistive sensors are particularly suitable for low pressures in the mbar range and when higher accuracy is required.

Pressure connection / process connection: The pressure port connects the pressure gauge to the process where the pressure is to be measured. The pressure transducer inside the transmitter must be tightly connected to the pressure port (welded or with elastomer seals). There are countless different pressure connections on the market, whose geometry and dimensions are specified in standards (e. g. the pressure gauge connection in DIN EN 837-1). In addition to industry-specific preferences, the decisive factor in the choice of connections is above all the type of seal: metallic sealing or with elastomer seals. The metallic seals are either conical threads or sealing cones. They are each mechanically deformed by the counterpart in such a way that a sealing effect is created. For pressures above 1'000bar, metallic sealing solutions are usually chosen.

Elastomer seals – also known as O-rings or profile seals – use cylindrical mounting threads. In a groove, the elastomer seal is compressed during assembly so that a sealing effect is created. The elastomer material must be selected so that it is compatible with the measured media and seals over the entire temperature range.

Most pressure connections are designed so that the pressure transducer is connected to the measured medium with a pressure channel bore. However, if pressure or level is to be measured on highly viscous, pasty or crystallizing liquids, flush process connections are used. You can read more about this in this article.

Electrical connection: There is less variety in the electrical connection because each industry segment uses only a few connector types. In general, it can be said that cable versions directly on the pressure transmitter are used less frequently because the cabling is more complex than for versions with connectors.

Main criteria for the selection of the suitable connection are the tightness against liquids and dust, the vibration resistance as well as the costs of measuring device and cabling including commissioning. A special requirement for pressure transmitters can be the correct pressure equalization from the transmitter interior and the environment: In practice, many electrical connections can cause unexpected problems when measuring pressure.

Trafag offers a wide range of different models, designs and variants as well as matching accessories to ideally meet the requirements in each application area.

Our pressure measurement experts will be happy to explain the differences between our products and advise you on which device is best suited to reliably fulfill your demanding measurement task.

Results

41 Articles found

-

IO-Link Pressure Transmitter and SwitchNAI 8273

-

IO-Link Flush Membrane Transmitter and SwitchFPI 8237

-

Flush Membrane TransmitterFPT 8236

-

Hydrogen Pressure TransmitterNHT 8250Approval / conformity: EC79/2009: e1*79/2009*406/2010*00047*00

-

Industrial Pressure TransmitterNAT 8252

-

Pressure TransmitterNAH 8253

-

Pressure TransmitterNAH 8254

-

Pressure transmitter for highly dynamic pressure curvesNAH 8254 20 kHz

-

Marine Pressure TransmitterNAE 8256Approval / conformity: DNV EU RO Mutual Recognition Type Approval Certificate

-

-

Railway Pressure TransmitterNAR 8258Approval / conformity: EN 50155 (Railway) EN 45545-2 (Fire protection) EN 61373 (Shock, vibration) EN 50121-3-2 (EMC)

-