Trafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

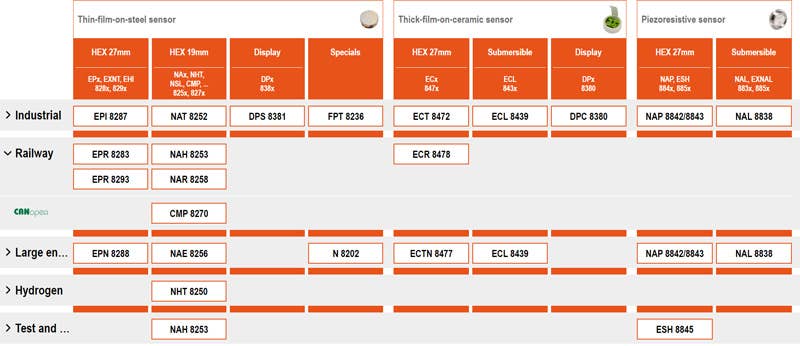

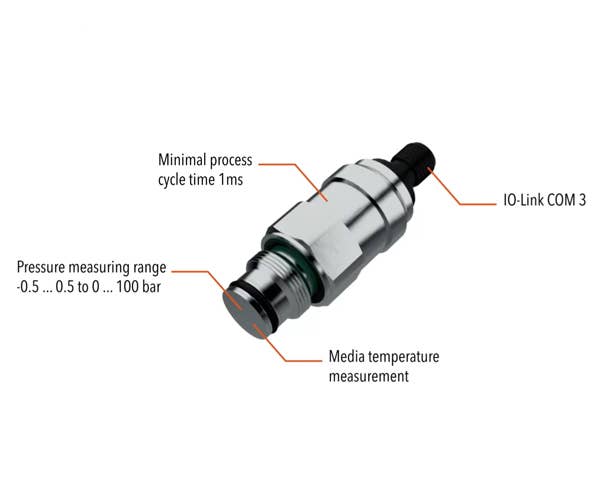

Trafag is your specialist for highly precise and robust pressure transmitters

How does a pressure transmitter work?

Products

Sensors for pressure, temperature and gas density is what Trafag stands for.

Decades of experience and our clear focus allow us to constantly improve quality and performance of our products and processes. And you get instruments which are built to last where others fail, with a long-term accuracy and robustness you can rely on.

Industries

News

Current information about our product innovations and news from the company.

See our latest news-

VIEW DETAILS

Trafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

-

Posted: February 26, 2024Categories: CompanyVIEW DETAILS

Trafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

VIEW DETAILSTrafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

-

Posted: October 02, 2023Categories: ProductsVIEW DETAILS

Trafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

VIEW DETAILSTrafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

-

Posted: August 31, 2023Categories: ProductsVIEW DETAILS

Trafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

VIEW DETAILSTrafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

-

Posted: August 17, 2023Categories: ProductsVIEW DETAILS

Trafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

VIEW DETAILSTrafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

-

Posted: May 11, 2023Categories: ProductsVIEW DETAILS

Trafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

VIEW DETAILSTrafag introduces innovative gas density monitoring solution for enhanced safety and efficiency

Events

As an international key player in the industry, we attend various trade shows. We would love to see you at one of them. Check our agenda now!

Career

Are you looking for your next career step?

Get in touch with us and learn more about our team spirit, our company culture and about job opportunities.