Know-how

In our know-how area you will find white papers, videos on products and functions, technical articles, explanations of terms and much more. This area is constantly being expanded.

-

Posted: April 11, 2024Categories: Pressure / Temperature

-

Posted: July 20, 2023Categories: Pressure / Temperature

-

Posted: January 05, 2023Categories: Pressure / Temperature

-

Posted: April 04, 2022Categories: Pressure / TemperatureView details

With the increasing popularity of hydrogen as an energy carrier, the need for suitable pressure sensors is also increasing.

-

Posted: February 15, 2022Categories: Pressure / Temperature

-

Posted: January 04, 2022Categories: Pressure / Temperature

-

Posted: December 20, 2021Categories: Pressure / TemperatureView details

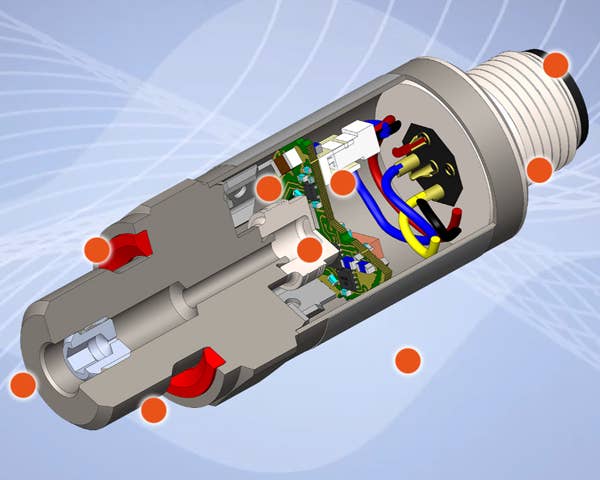

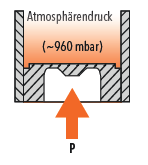

Venting pressure transmitters? The reasons behind the process and the technical solutions on offer.

-

Posted: February 10, 2021Categories: Pressure / Temperature

-

Posted: February 04, 2021Categories: Pressure / TemperatureView details

Smartphone-enabled display pressure switches simplify both the commissioning process and the handling of spare parts.

-

Posted: January 20, 2021Categories: Pressure / TemperatureView details

Amazing new solutions for well-known problems in hydrostatic filling level measurement are possible: On the one hand by using a smartphone app. On the other hand through the use of a tried and tested cable gland from the process- and chemical engineering sector.

-

Posted: November 16, 2020Categories: Pressure / TemperatureView details

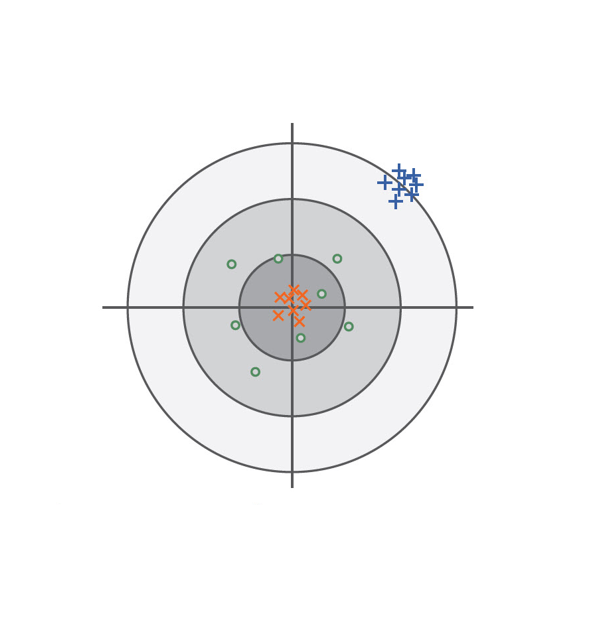

Data sheets from manufacturers of pressure transmitters often contain many different specifications on the subject of accuracy. In most cases, however, not all information is relevant. This article explains which information is to be taken into account and when. It also explains why long-term stable pressure transmitters are a prerequisite for cost optimization in demanding industrial applications.

-

Posted: November 12, 2020Categories: Pressure / TemperatureView details

A common problem in applications with water, oil, or other liquids are brief pressure peaks, which are so high that they damage the measuring cell of pressure transmitters. If pressure peaks of this kind occur, a pressure transmitter with maximum overpressure resistance, which requires a very long-term stable measuring cell and powerful electronics, must be used.