Insulating gas / SF6 gas density monitors & sensors – Frequently asked questions and answers

Do you have any questions on gas density monitors or sensors? First answers can be found here in our FAQ.

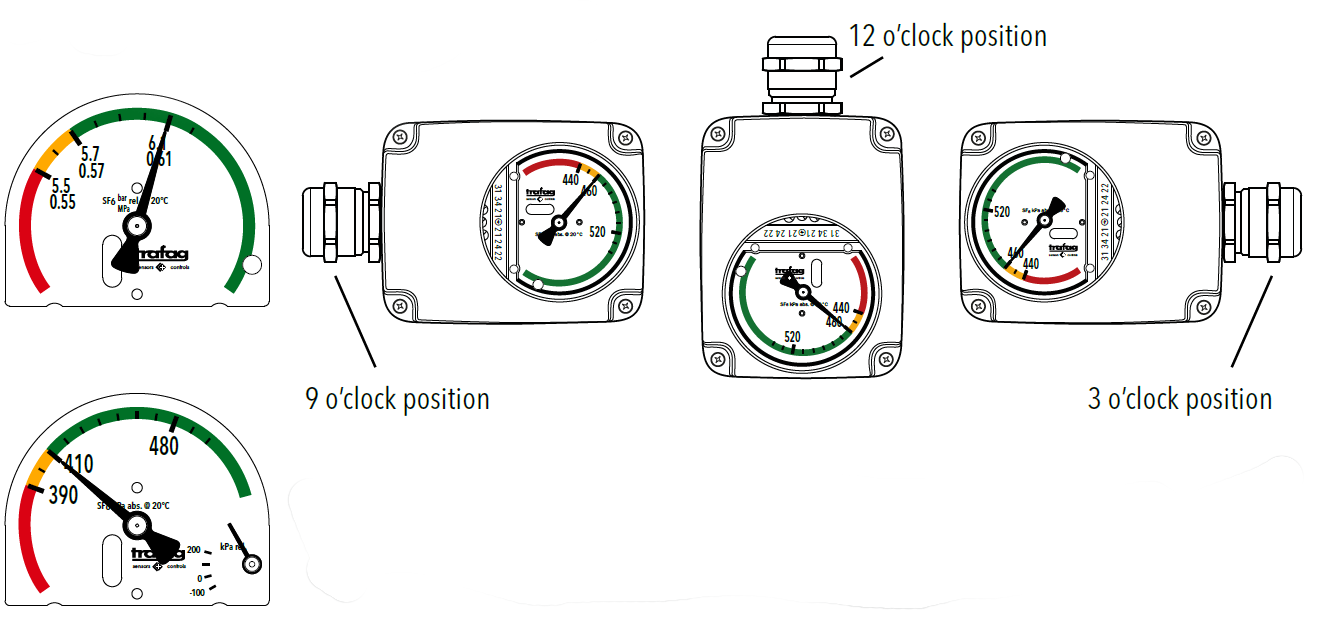

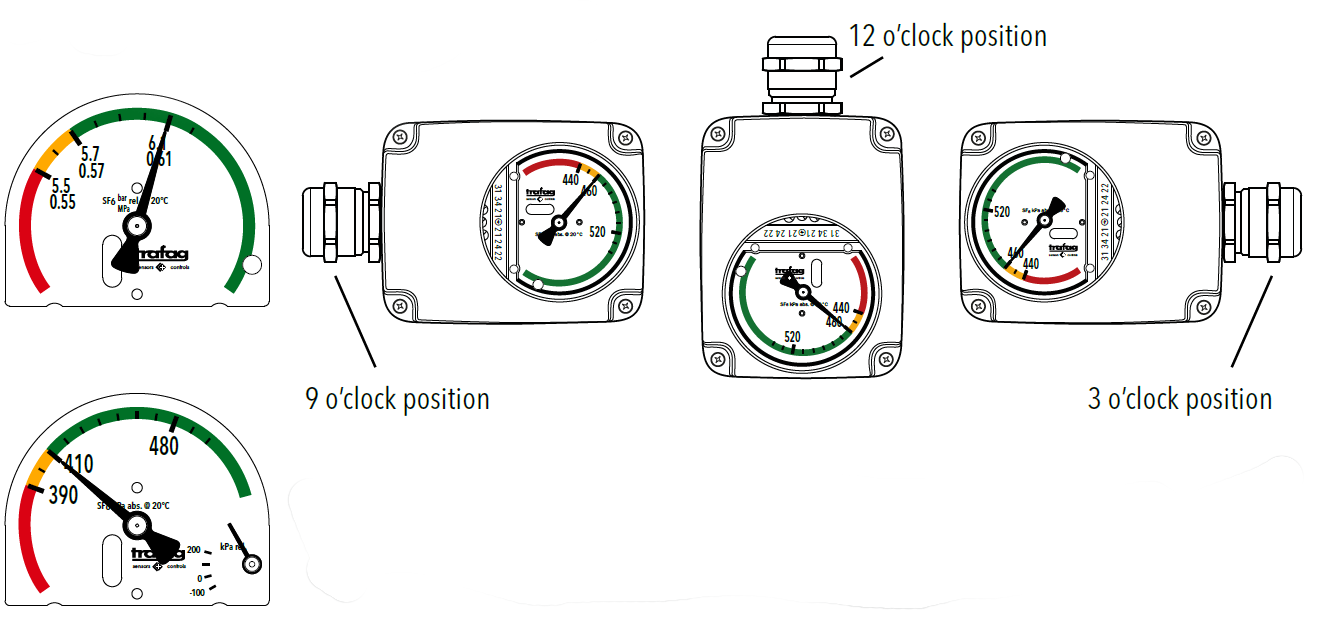

Trafag provides maximum flexibility in customization for the indicator dial with a full variety of colour codings and pressure units including dual range indication. This also includes rotated dial orientation by 90°/180°/270° to provide best readability for restricted installations.

An optional low-pressure indicator monitors conditions aside normal operation e.g. while compartment is filled with transport pressure or being vacuumed.

How do gas density monitors perform in low-pressure and extreme temperature conditions?

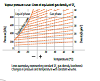

Arctic climate presents the highest requirements to gas compartment and density monitoring. The main safety aspect is the alarm when the insulating gas may liquefy.

Low temperatures can lead to liquefaction of process gas. Liquefaction causes a rapid pressure-drop that can temporarily trigger an alarm switchpoint. Gas density monitor 87x8 keeps the alarm status until the alarm trigger level is exceeded again while returning to normal condition.

![Diagram: Pressure [kPa] / Temperature [°C] of Liquefaction curve](https://www.trafag.com/media/Knowhow/faq-gas-density/liquid-phase.png)

![Diagram: Pressure [kPa] / Temperature [°C] of Liquefaction curve](https://www.trafag.com/media/Knowhow/faq-gas-density/liquid-phase.png)

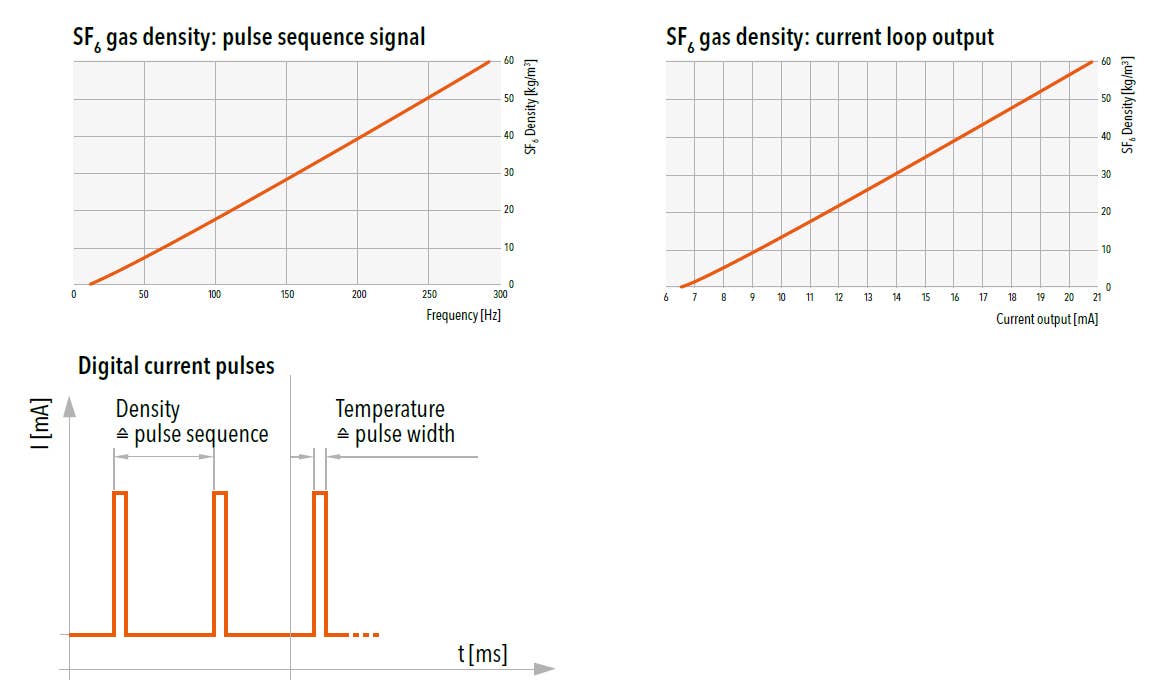

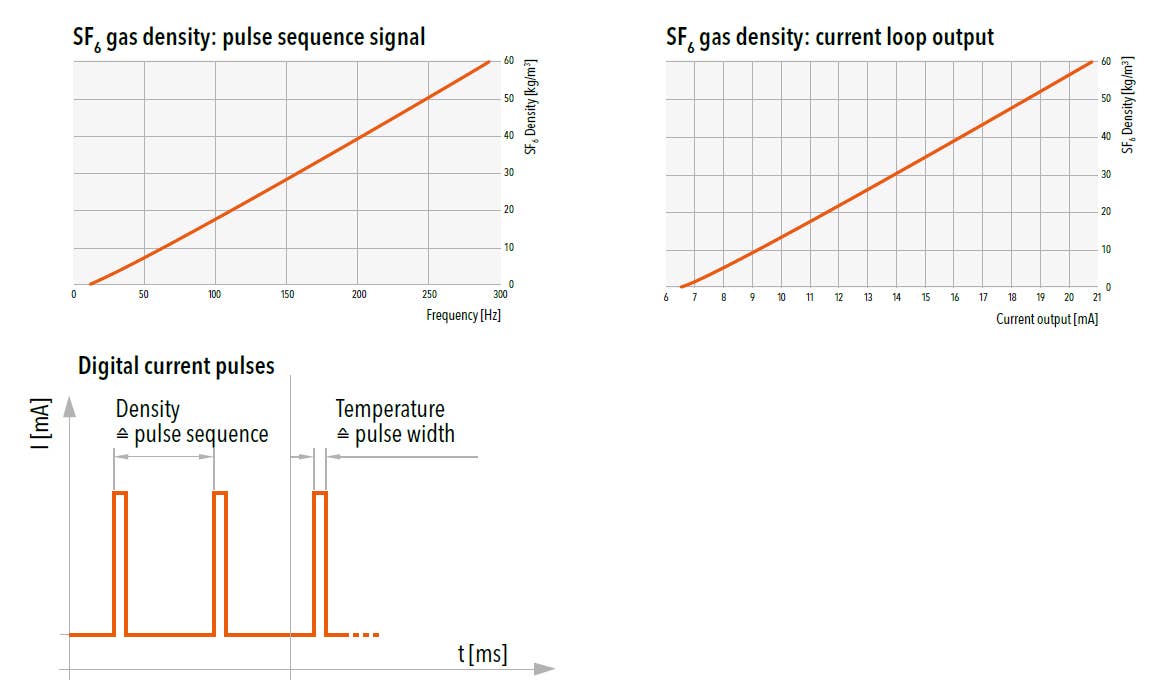

What signal outputs are available for gas density sensors?

The digital pulse-width modulation features density and temperature data. Trafag provides conversion formulas for gas density, standardised gas pressure @ 20°C for SF6 or alternative insulating gases and for the conversion of pulse-width to temperature.

The current loop output has a resolution of 6.5 … 20mA. Trafag provides conversion formulas for gas density and standardised gas pressure @ 20°C for SF6 and alternative insulating gases.

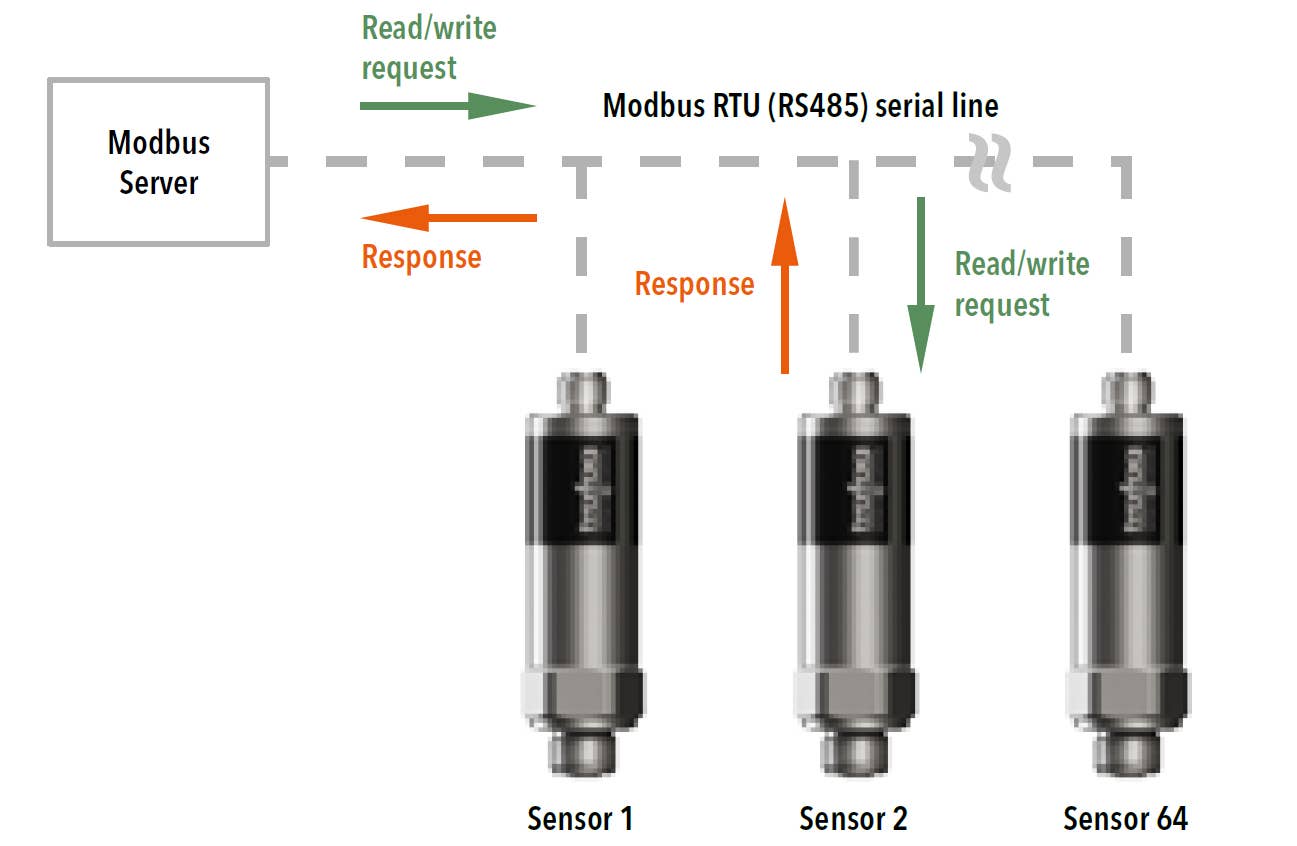

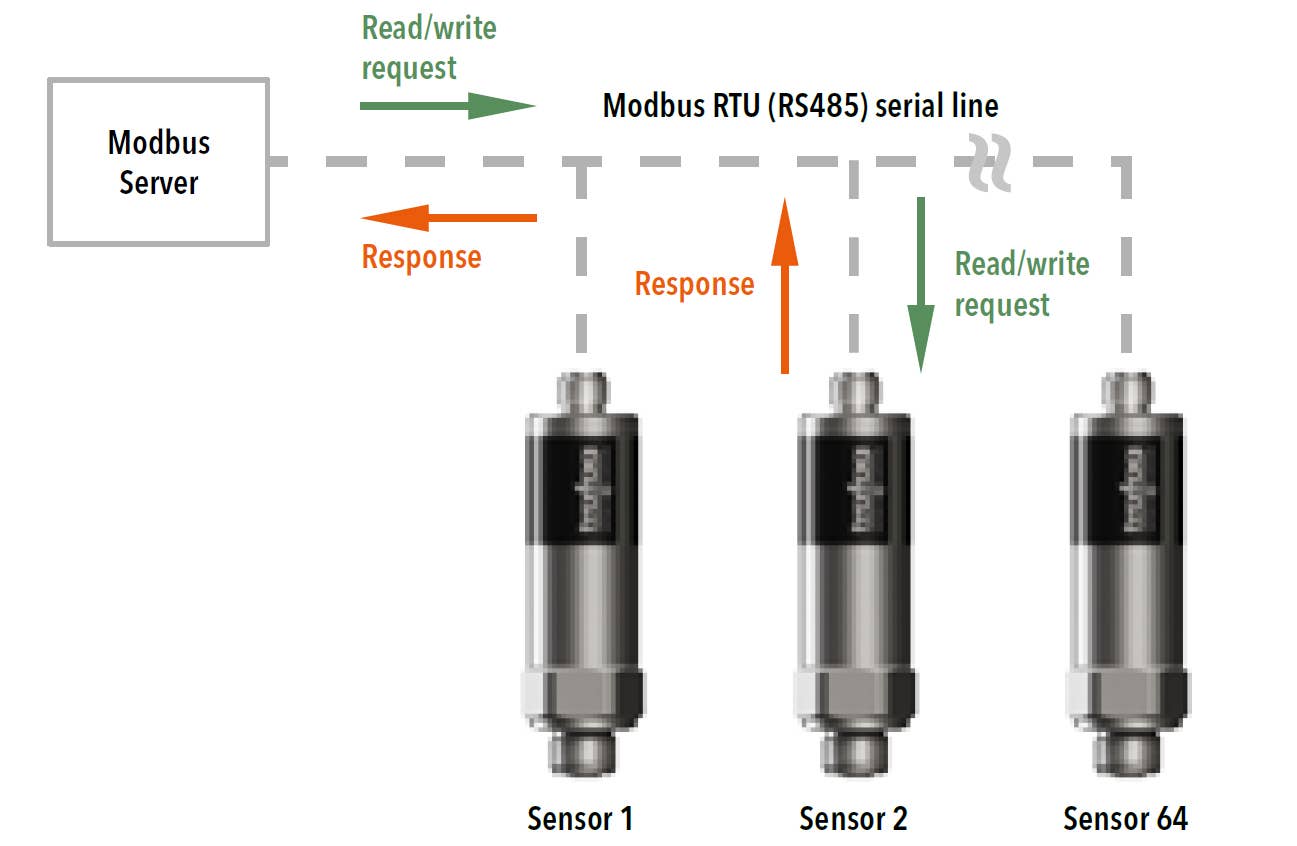

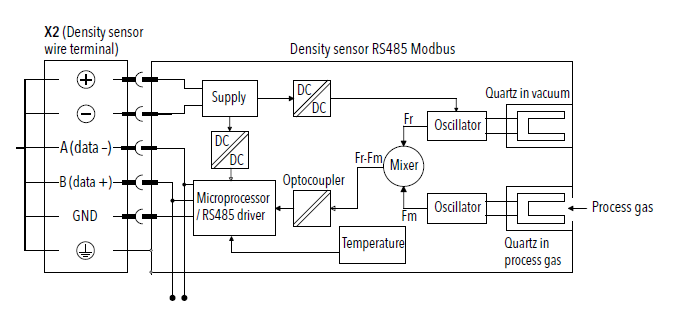

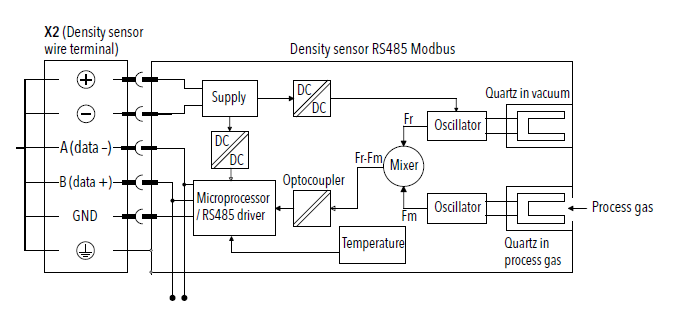

How is density and temperature data transmitted and integrated, including Modbus protocol?

The open available Modbus protocol is the ideal communication layer for transmitting data between electronic devices over serial RS485 lines. It is a client/ server protocol. One client controls the data transactions with multiple servers (sensors) that respond to the client's requests (read or write data). In a standard Modbus serial network, there is one client and up to 64 servers (sensors), each with a unique server address.

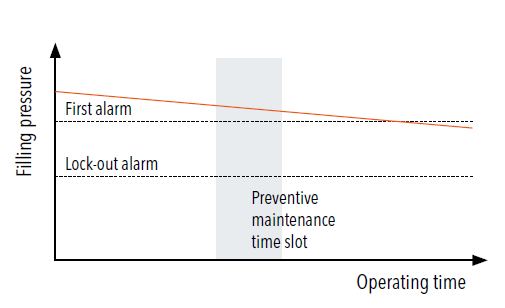

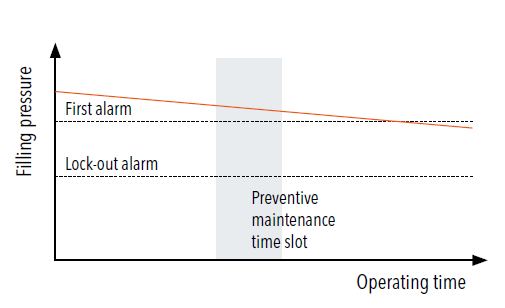

How is gas density measurement used for preventive maintenance?

Density measurement is provided via 2-wire current loop output. It provides essential trend information of potential gas losses or gear status and therefore allows to determine preventive maintenance measures.

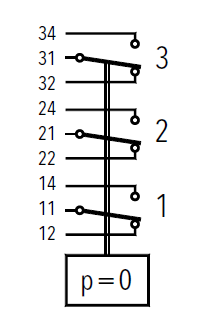

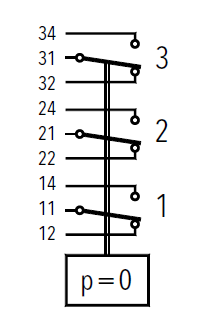

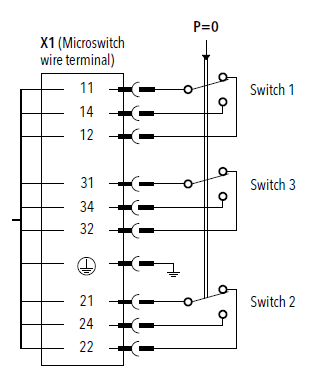

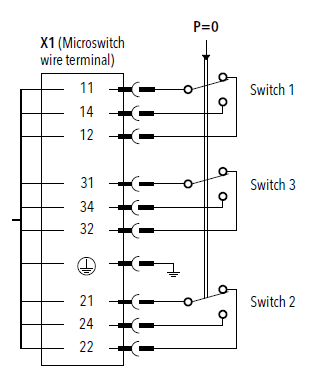

Density monitoring is based on up to three galvanically isolated microswitches that actuate different alarm signals.

Density monitoring microswitches and sensor data signal are separated by independent wire terminals.

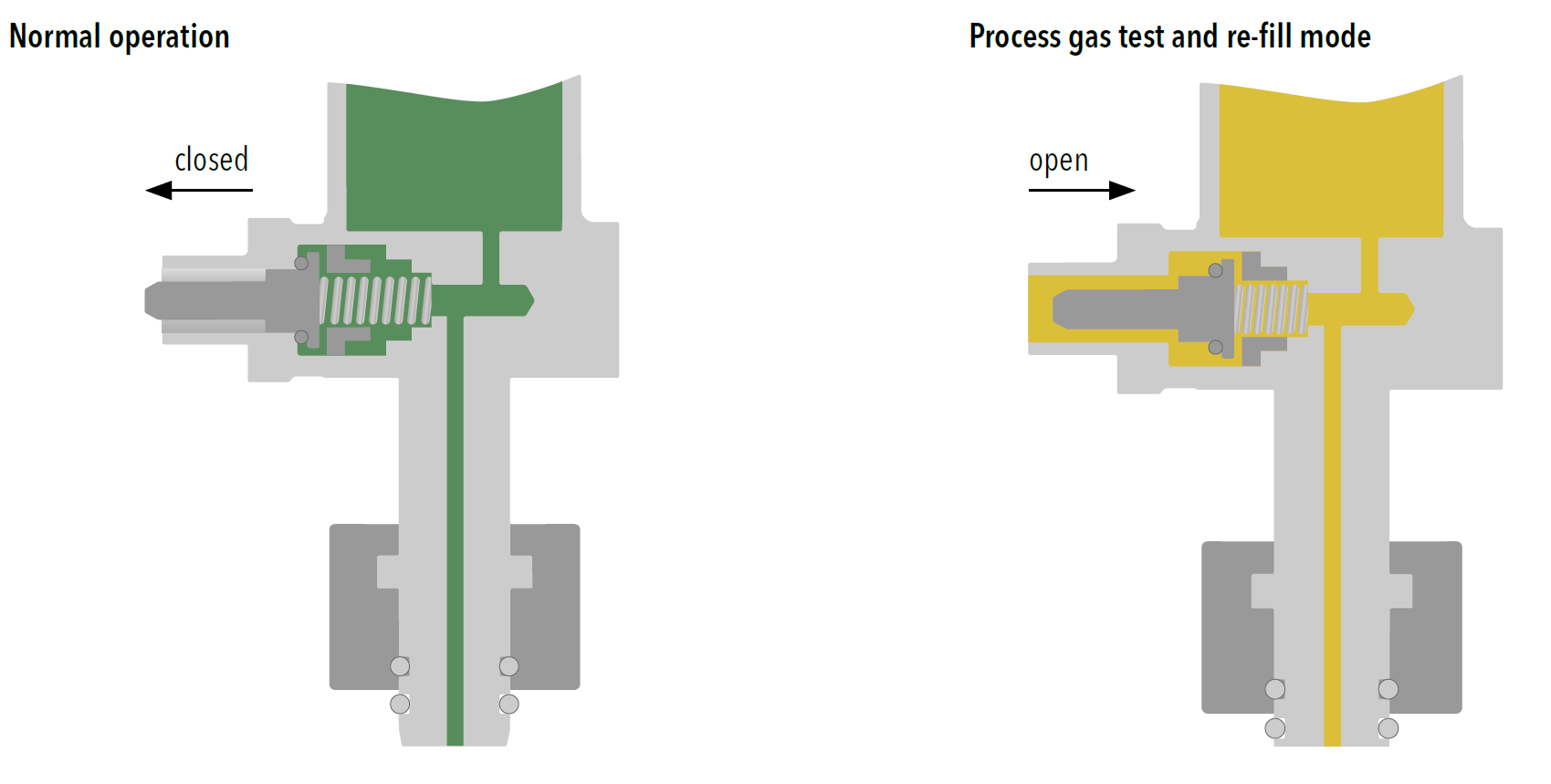

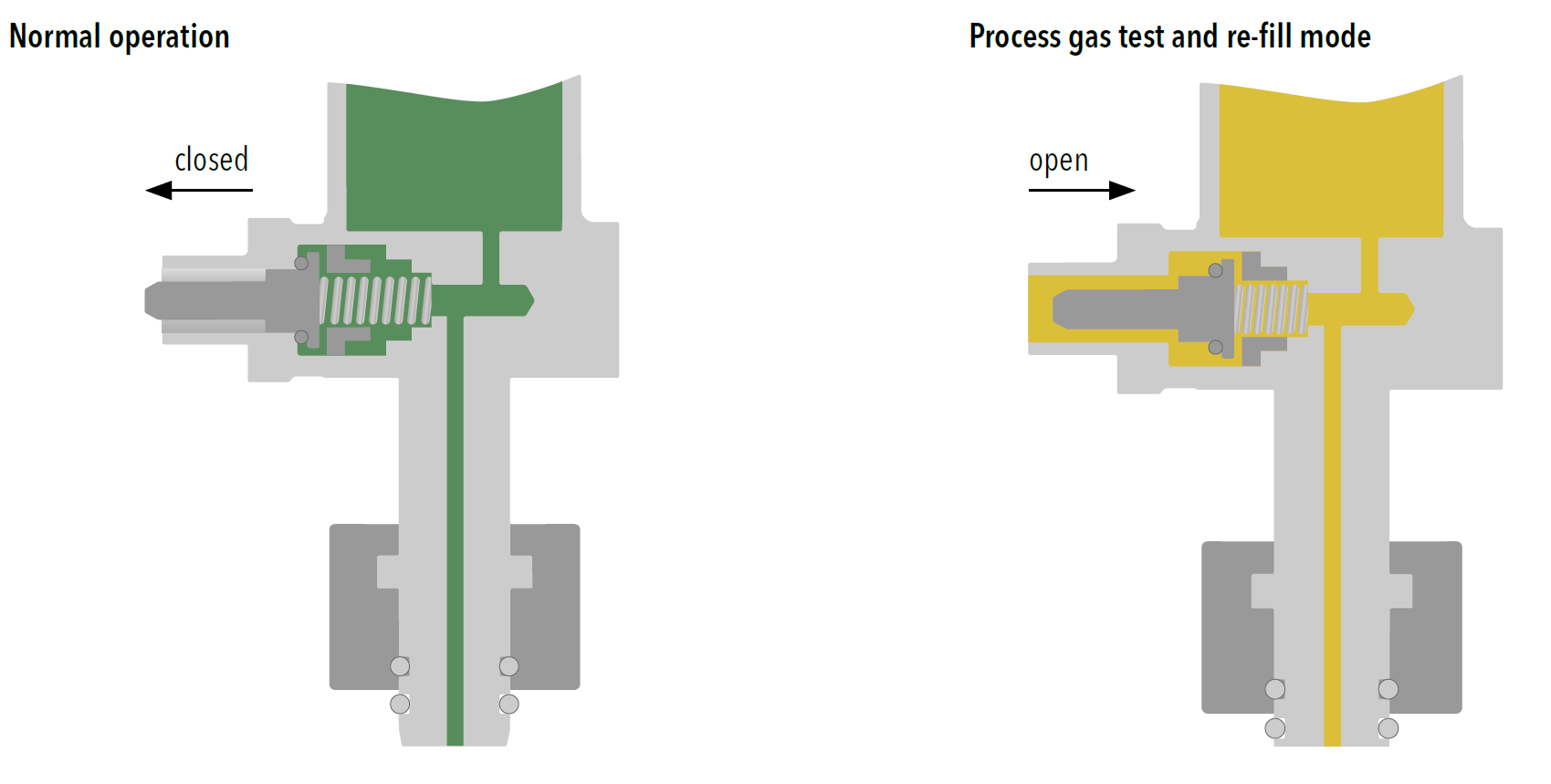

Functions of the test and refill valve in SF6 gas density monitors

The test and re-fill valve offers two essential functionalities. Firstly, it provides the capability to analyze in-situ the gas quality of the pressure compartment. On the other hand, it is a re-filling valve that allows direct insulating gas replenishment of the pressure compartment. Test or re-fill equipment is connected via a standardised DN8 port during normal operation under nominal system pressure.

If you have further questions, do not hesitate to contact us.