Lower emissions in shipping thanks to future fuels

Shipping plays a crucial role in the global economy, as it accounts for 90% of global trade. The challenge is that it also causes 3% of all greenhouse gas emissions. The International Maritime Organization (IMO) has adopted a strategy to reduce emissions. Alternative fuels play a major role in this.

(Excerpt from the sustainability brochure)

In order to reduce the impact of shipping on the environment, the IMO has adopted a strategy to reduce greenhouse gas emissions. On the one hand, ship design is to be optimised so that less fuel is consumed. On the other hand, the main focus is on the fuel itself: In view of increasing environmental regulations and a growing social awareness of sustainability, traditional fossil fuels are no longer fit for purpose.

Future fuels – alternative, low-emission or even emission-free fuels – offer innovative solutions to drastically reduce CO2 emissionsin shipping. However, they also present challenges. For example, an appropriate infrastructure for refuelling ships must be available on land. And production must also be economical and sustainable. In addition, the fuel must not only be environmentally friendly and cost-effective, but must also be able to be stored safely on board and in sufficient quantities for long journeys. Engines have already been developed that can run on alternative fuels.

Suitable alternative fuels for large cargo ships

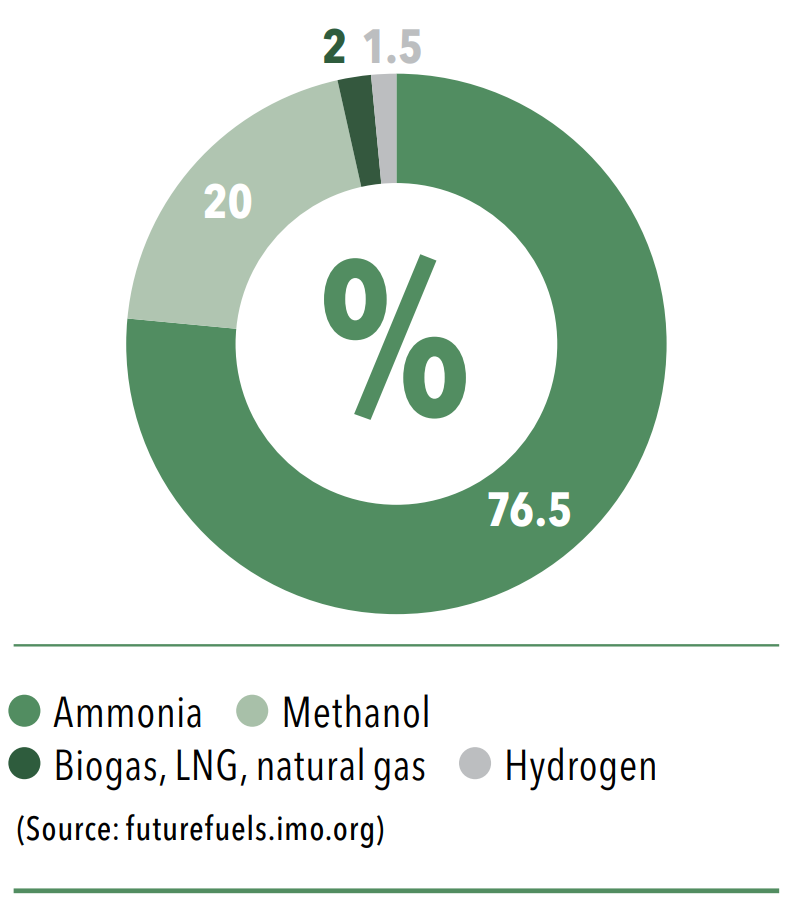

For large cargo ships, which in the past were primarily fuelled with heavy fuel oil (HFO), three alternative fuels are primarily available: Liquefied natural gas (LNG), methanol and ammonia. Hydrogen, on the other hand, is currently considered unsuitable for large ships or longer distances because it has a low energy density and hydrogen tanks would therefore take up too much space on the ship. LNG, on the other hand, is already being used on a large scale today, particularly in dual-fuel engines. These can be operated with both LNG and liquid fuels such as HFO or marine diesel. Methanol as a fuel offers emission advantages, is already readily available and is relatively similar to today’s fuels, especially in terms of handling and combustion, which reduces development times and risks. In the longer term, ammonia (NH3) is an interesting alternative because, unlike carbon-based methanol, it does not produce CO2 during direct combustion.

It can also be produced in large quantities from environmentally friendly hydrogen using conventional processes. Ammonia also has a much higher energy density than hydrogen and can therefore be stored and transported more economically. However, it is very toxic and has combustion properties that pose particular challenges in the development and operation of engines and ships.

As large cargo ships are built for a service life of 20 to 40 years and it is not yet clear which fuels will prevail in the long term, today’s ship engines are often designed for several fuels. In addition, some of the existing fleet will be converted over the next few years so that older engines can also be operated with future fuels.

What significance does this have for pressure measurement?

Due to the different chemical and physical properties of the new fuels, the pressure measurement on the engines and units must also be adapted. While existing technologies and products can still largely be used for LNG and methanol, new pressure transmitters must be developed and integrated in some cases for engines fuelled with ammonia. The measuring cell of the pressure transmitter is made of stainless steel and is completely welded. It is not damaged by ammonia. However, the elastomers currently used as sealing materials are not suitable for contact with ammonia. In order to avoid any leaks, the sealing geometry must therefore be adapted or sealed double chambers must be used.

In addition, the risk of explosion is greater with ammonia than with HFO. Therefore, appropriately certified pressure transmitters must be used more frequently with ammonia-powered engines. Trafag works closely with renowned marine engine manufacturers to develop customised pressure transmitters that are safe, reliable, accurate and cost-effective. Trafag’s many years of experience in sensor development, its expertise in important core technologies and flexible manufacturing enable it to quickly develop solutions with a high degree of maturity and thus shorten the development time for new engines. In this way, Trafag is making an important contribution to the transition to more environmentally friendly fuels in shipping.

Trafag Sustainability Brochure

Contact us

Do you have questions about hydrogen and/or hydrogen pressure transmitters? Our specialists will be happy to provide you with expert advice.