Wireless retrofit for micro-leakage detection

Thanks to specialised algorithms and many years of experience in monitoring energy supply systems, Gomero — together with Trafag density sensors — detects micro-leakages in highvoltage switchgear. This enables customers to carry out optimal, needs-based maintenance. The key factors for success are Gomero’s algorithms and the reliability, accuracy, and stability of Trafag’s density sensors. Another decisive factor was the open, efficient, and professional collaboration, as well as the excellent support Gomero received from Trafag and Regal. This interview provides insights into the collaboration between Gomero, Regal, and Trafag with aftermarket customers.

«Since 2008, Trafag AG has been a trusted supplier to Regal Components, fostering a strong and close partnership over the years. Trafag’s reliable, high-quality sensors play a crucial role for Gomero, enabling them to collect accurate data for their innovative system solutions.»

Maximilian Grudin, Sales Manager Regal

Gomero has developed an innovative solution for monitoring insulating gas leaks. What made collaborating with Trafag so valuable for your system?

Malin (Gomero): «The collaboration with Trafag has been valuable on several levels. They were recommended by our customers, which gave us strong confidence from the start. Trafag also has long experience in the market, which speaks to their reliability. Their sensors are robust and maintain high quality, which is exactly what we need. We have validated their performance, and they consistently deliver excellent results.»

Maximilian (Regal): «Since 2008, Trafag AG has been a trusted supplier to Regal Components, fostering a strong and close partnership over the years. Trafag’s reliable, high-quality sensors play a crucial role for Gomero, enabling them to collect accurate data for their innovative system solutions.»

Malin: «A crucial part has also been the support we received through Regal. They have contributed technical expertise and helped us understand customer needs and installation requirements for different manufacturers and models. Their commitment has been invaluable and has made our complete solution work seamlessly for the customer. It is precisely this type of collaboration, where all parties take shared responsibility, that enables us to deliver the best possible solution.».

The gas density sensors, together with the AI-powered software algorithms you developed, form the basis for micro-leak detection. Could you please briefly explain how this works?

Malin: «Our solution is based on collecting data, filtering out noise from temperature and other external factors, and using our field experience to understand which parameters affect measurements and when it’s best to take them. Through filtering and AI algorithms, we can distinguish real leaks from natural variations. It’s about interpreting measurement values in their context, since gas density is affected by factors such as weather, solar radiation, and how often a switch is used. Sensor values alone are not enough; we must be able to filter out natural noise to identify actual micro-leaks. That’s what our solution enables.»

Andreas (Trafag): «One particular challenge which Gomero very successfully solved is the small fluctuations during the day due to ambient temperature changes. During these temperature changes, the switchgear does not heat up evenly; instead, certain areas react more quickly to temperature changes than others. The uneven temperature distribution in the gas chamber, where the pressure is the same throughout, means that the local density of the gas can vary until stationary thermal conditions prevail again.»

What was the decisive technical reason for choosing the Trafag gas density sensor?

Malin: «Beyond the fact that Trafag’s sensors are robust and reliable, it was their technical solution that became decisive. The sensors measure both temperature and gas density, and we can use a formula at the system level, adapted to the specific gas, to convert density to pressure. This means we can support different gases and mixtures without needing to change sensors in the field. All configuration is done centrally, which provides great flexibility and makes the solution very scalable and cost-effective.»

Maximilian: «Our primary role was to support Gomero in evaluating available options and ensuring the seamless technical integration of the sensor into their system. Trafag’s solution met all the technical requirements and could be effortlessly implemented into Gomero’s monitoring system. The combination of density and temperature measurement, along with centralised configuration capabilities, made it a technically robust and future-proof choice.»

Johannes (Trafag): «From a commercial and strategic point of view, one of Trafag’s biggest strengths is combining proven technical reliability with global availability. Our sensors are trusted by all major OEMs and deliver consistent quality worldwide, giving partners like Gomero the confidence to scale their solutions without requalification or complex sourcing. This combination of robust technology, flexibility, and close cooperation made the partnership a natural fit.»

Why are stable, non-drifting gas density sensors so important?

Malin: «Stability over time is crucial when detecting small changes. We must be able to trust that a deviating value really is due to a leak, not the sensor’s own drift. If we want to reduce field visits and offer cost-effective monitoring, we need sensors that function reliably without requiring recurring calibration. Otherwise, we risk false alarms or missed leaks, and then the entire value of remote monitoring falls apart.»

Andreas: «As the monitored infrastructure in high-voltage grids is operated over many years — often decades — drift-free sensors are decisive for condition monitoring. Even a slight drift of a sensor will accumulate over time to a level which makes recalibration or replacement of the sensor inevitable. Unlike common pressure sensors, Trafag density sensors are based on the drift-free quartz tuning fork measuring principle, which makes them the ideal choice for this application.»

Can your system also detect micro-leaks of alternative gases?

Malin: «Since we convert gas density to pressure at the system level, we can adapt the algorithms for different gases and mixtures. SF6 is most common, but in colder climates, nitrogen mixtures are sometimes used for better insulation properties at very low temperatures. Trafag’s sensors deliver the density value to us, and we use the right formula for each gas. This way, we can use the same hardware and algorithms, making the solution very flexible.»

Andreas: «Trafag’s density sensors have a very wide measuring range per design, and the measuring principle is completely independent of the specific gas. The generic sensor signal can be converted to the gas specific density either as Gomero does in the monitoring solution software or directly in the density sensor. Additionally, the sensors with digital output provide the sensor temperature which can give valuable information about the environmental conditions.»

What advantages do your customers see in implementing your solution, and what can grid operators expect from it in future?

Malin: «Our solution is scalable and easy to build upon. Once the technology is in place, it’s quick to connect additional signals and sensors without starting over for each new application. Customers get faster and more accurate information about their installations, making it possible to act proactively and plan maintenance better. At the same time, the need for physical field interventions decreases. This enables a shift from traditional, reactive maintenance to data-driven and needs-based monitoring, something that becomes increasingly important as requirements for both robustness and sustainability in energy systems increase.»

Maximilian: «From my experience, grid operators highly value solutions that minimize unplanned downtime and reduce the need for on-site work. They also appreciate systems that can evolve with their needs without requiring costly hardware replacements. Gomero’s approach, incorporating Trafag’s sensor technology, instills confidence that the data driving their decisions is accurate and reliable, a critical factor in advancing toward predictive, data-driven maintenance.»

Johannes: «Gomero’s approach shows exactly what we at Trafag value in strong partnerships: agility, transparency, and a shared focus on customer benefit. Together with our global partner network, including Regal, we ensure fast local support and long-term security of supply. For grid operators, this means reliable data, fewer site visits, and a sustainable, future-proof solution. This mix of trusted technology and local expertise is what makes Trafag the preferred supplier to many OEMs and system integrators worldwide.»

What developments do you generally expect in SF6 monitoring in the coming years?

Malin: «SF6 monitoring is becoming increasingly important, especially with stricter environmental requirements and the EU’s so-called F-gas regulation. This drives the need for better tools to monitor and minimize emissions. With reliable sensors and AI-based analysis, we can offer a completely new level of monitoring, including micro-leak detection, something that was previously very difficult. By collecting large amounts of data and analyzing it in context, we gain better insight and can act more precisely. Our solution is also retrofit-compatible, which means it can be implemented on existing installations without major modifications. We see a clear development toward more intelligent systems, where more data leads to even better precision and value over time.»

Andreas: «The grid infrastructure in many countries has been in operation for many decades. To extend its lifetime, but also to minimize operational cost by optimising maintenance and service intervals, grid operators want to monitor all assets more closely and with live data. We see a significantly increasing demand for electronic density sensors and hybrid density monitors which enable exactly this continuous monitoring. The electronic density sensors are ideal for retrofitting where the operational safety switches of the original density monitor are used, whereas the hybrid density monitors are typically for new installations and cover both the operational safety functions with the mechanical switching outputs as well as the continuous monitoring for preventive maintenance.»

Maximilian: «Looking ahead, I anticipate SF6 monitoring to become more connected and data-driven, with deeper integration into digital asset management systems and a growing focus on predictive analytics to prevent failures before they occur. As the industry transitions to SF6 alternatives and mixed gases, the demand for flexible sensors capable of handling multiple gases without hardware changes will increase rapidly. Trafag’s non-drifting sensor technology, based on quartz forks, combined with Gomero’s solution, already supports this need, providing operators with a future-proof approach from the start.»

Johannes: «We clearly see the market moving toward more digital, connected, and sustainable monitoring solutions. Trafag’s role is to be the stable technology backbone behind this shift while remaining agile and responsive to our partners’ needs. With our hybrid and electronic density sensors, we support both retrofit projects and new installations, ensuring a smooth transition toward data-driven maintenance. Working closely with leading OEMs and solution providers like Gomero allows us to adapt quickly to new gas types and regulations and to help utilities reach their environmental and operational goals efficiently.»

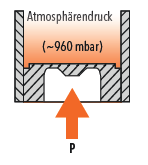

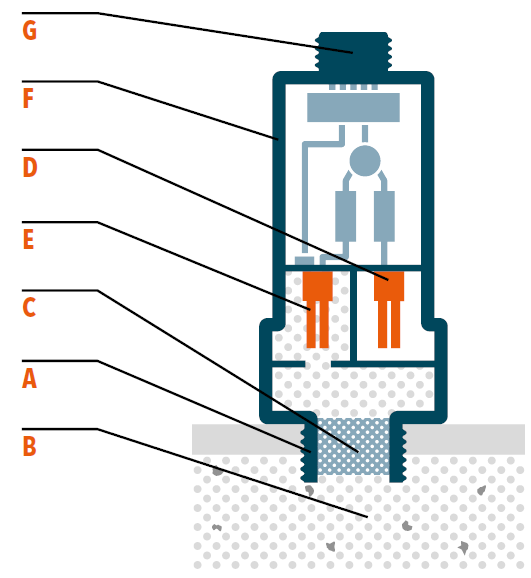

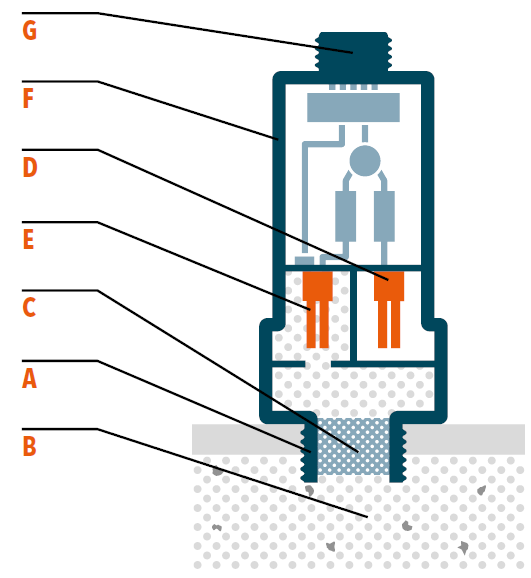

Functional principle of Trafag’s gas density sensor

The density sensor is mounted to the gas-filled pressure chamber B via an adaptable process connection A with a filter element C against aggressive byproducts. Trafag density sensors operate on the principle of comparing the constant resonance frequency of a quartz oscillator under vacuum D with the resonance frequency of an identical quartz oscillator surrounded by insulating gas E. Gas of different densities affects the preset resonance frequency of the quartz oscillator surrounded by the insulating gas. The response time for detecting density changes is less than 10 ms. The shift in resonance frequency is proportional to the density of the insulating gas being measured and is evaluated by the sensor’s electronics F. The evaluation electronics include an additional temperature sensor. The measurement signal is provided through selectable electrical output connections G.

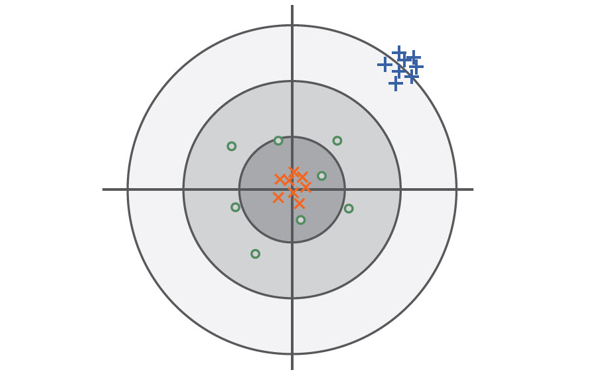

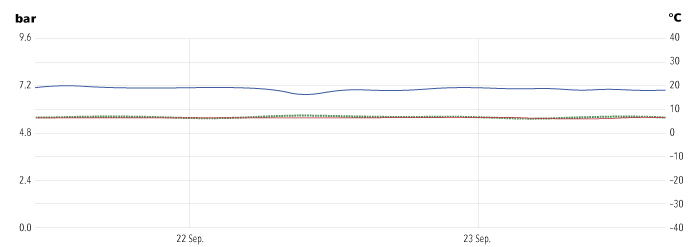

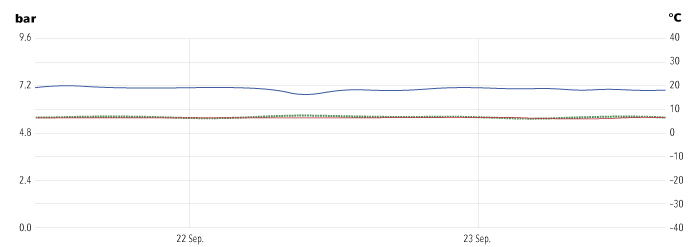

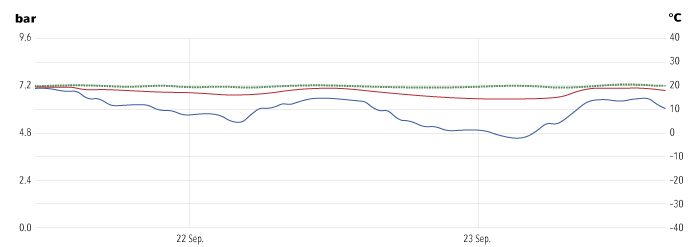

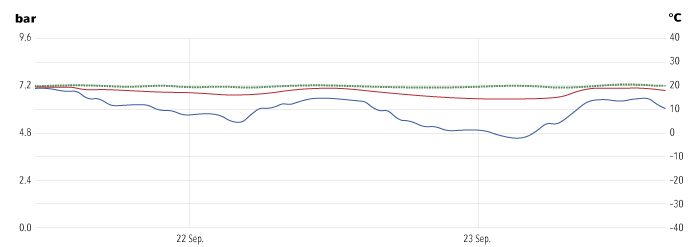

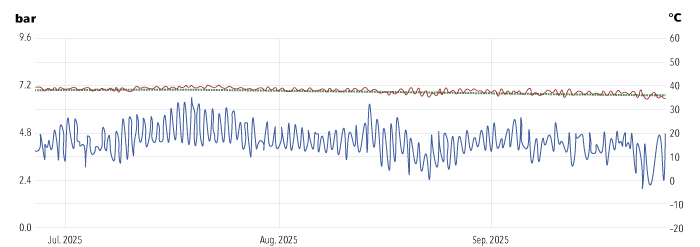

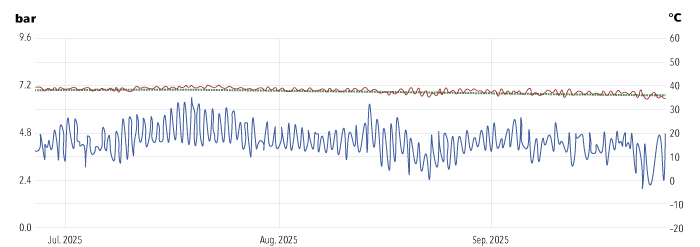

Daily measurement

The recording of the density measurement together with the temperature shows that the density measurement also fluctuates during the course of the day due to temperature changes. Even in an indoor facility with very low temperature fluctuations, the density signal is not completely constant. Gomero’s software smooths out these fluctuations (green area) using special algorithms that take into account both the measured temperature and other parameters.

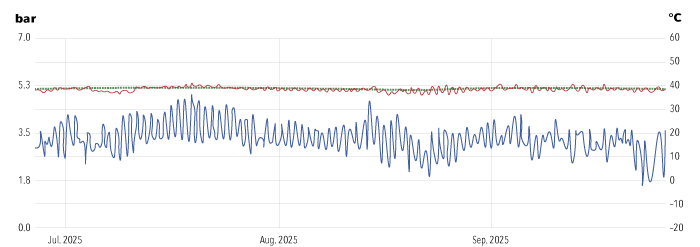

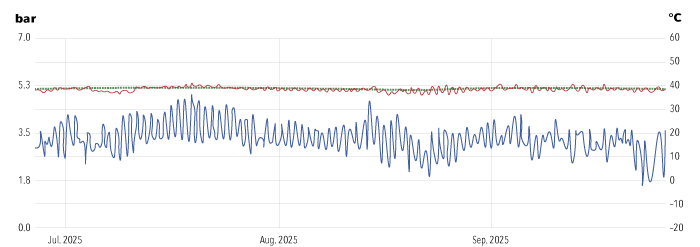

Measurement with no micro-leakage

The graph showing the course of the year indicates that there are no leaks in the chamber. The fluctuations in the sensor signal associated with daily and seasonal temperature changes are smoothed out by the Gomero software, indicating that there are no leaks.

Measurement with verified leakage

The leakage detected in this chamber is significantly smaller than the daily and seasonal variations caused by temperature changes. Detecting these micro-leaks requires not only sophisticated algorithms, but also absolutely drift-free sensors such as Trafag’s 8775 density sensor as an indispensable basis.

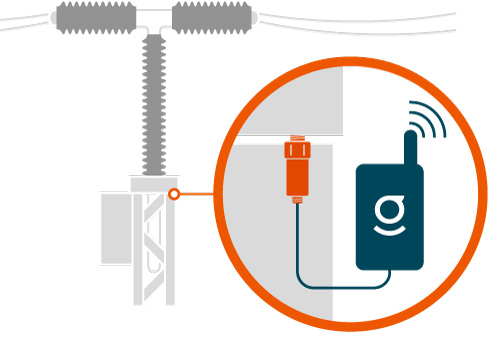

The Gomero monitoring system

The Gomero monitoring system can be installed very quickly, as the entire safety-critical density monitoring system remains untouched. All that is required is a connection A for the Trafag density sensor B in the gas chamber and a mounting option for the Gomero wireless module C to which the Trafag density sensor is connected. The system can be expanded with minimal impact on operations.

Why does Trafag’s density sensor not show a constant density, but fluctuates throughout the day and season, even though there is no leakage?

When the gas chamber of the switching unit warms up during the day, e.g. at sunrise in the morning, it does not warm up evenly, but varies depending on solar radiation, thermal mass distribution and heat transfer coefficients. This means that different temperatures prevail within the chamber during the transient phase. However, because the pressure is the same throughout the chamber, this leads to locally varying densities. Trafag’s density sensor measures the local density at a specific point. This measured value may differ from a pressure value measured with a pressure gauge, which is converted into density using the temperature (measured at a different point). Due to the inhomogeneous density distribution in the chamber during the temperature change, which also changes in the transient phase, ‘the density’ cannot be determined by local sensors in the unsteady state for physical reasons. In practice, this is usually not necessary, as safety-critical density monitoring is usually carried out using a mechanical density monitor, which compares the chamber pressure with the pressure in a reference chamber and is therefore not sensitive to the inhomogeneous density distribution in the plant chamber.

Density sensors that measure local densities are typically used for continuous monitoring to detect long- term trends. It is therefore particularly important that the values are reproducible and drift-free in order to be able to detect even the smallest changes in the chamber under the same conditions. The major advantage of direct density measurement using the Trafag principle with a quartz oscillator over pressure-temperature measurement is that, unlike pressure and temperature sensors, it is drift-free.

Gas Density Sensor 8775

Swiss based Trafag offers precise, reliable and maintenance-free instruments developed for density measuring of SF6 and related alternative gases. Measurement is based on the patented quartz tuning fork technology. Thus offering the most reliable and long term drift free solution on the market by directly measuring the insulating gas density

Gomero: With connected sensors, analytics, and artificial intelligence, we make predictive maintenance possible.

Gomero is a Swedish technology company specializing in intelligent systems and services for the energy sector. Gomero develops solutions for predictive maintenance of energy systems and infrastructure. Sensors and data analysis are used to record and evaluate conditions in order to make maintenance measures plannable and efficient. The technology is used in power grids, among other places, to prevent outages and extend the service life of systems.

Regal: We strive for simplicity with smarter technical solutions in sensors and electric drive systems.

Regal is a subsidiary of Axel Johnson International, which specialises in the development, production and system integration of high-quality sensor and electric drive solutions for machines and vehicles. Regal is known for its customised solutions that can be flexibly integrated into indus- trial applications.