Absolute electronic insulating gas density measurement based on the oscillating quartz principle

Safe and without interruption with Trafag density monitors

Starting in the mid-90s, Trafag introduced gas density sensors. They are the first choice when continuous and long-term, drift-free insulating gas density measurement and data acquisition are required. Exposure of an oscillating quartz to gases of different densities causes a shift and damping of the resonant frequency. The insulating gas densities of SF6 as well as those of alternative insulating gases can thus be measured directly and electronically.

The operational reliability and operational safety of gas-insulated high-voltage switchgear can only be guaranteed if the required gas density in the pressure compartments is maintained. Leakage would endanger the safety of the switchgear and at the same time violate environmental regulations. SF6 in particular is a potent greenhouse gas and must therefore not be released into the environment. Strict regulations regarding SF6 emissions (e.g. F-Gas 517/2014) must be observed and require permanent monitoring of the pressure compartments.

Gas density sensors determine the current status and transmit the measured values to a control system. This real-time data enables analysis of the operational availability of the plant and provides characteristic values for predictive maintenance. Continuous density measurement thus supplements the pure monitoring of the safety switching points. In addition to measuring SF6 gas density, the densities of commercial alternative insulating gases such as Greentric, EconiQ, Clean Air, g3 as well as CF4, N2 and CO2 can also be monitored.

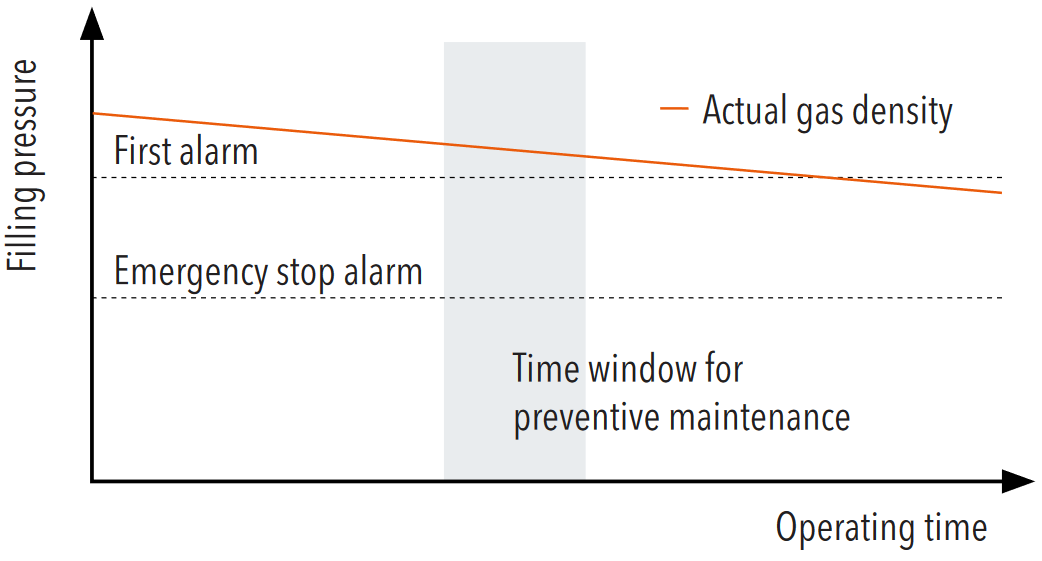

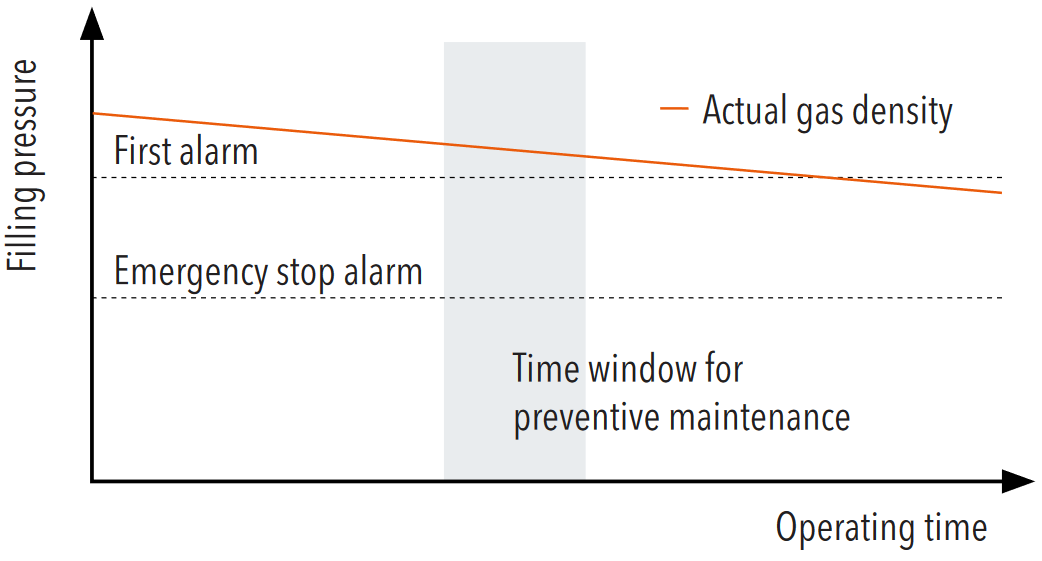

Why using continuous measurement of insulating gas density?

Continuous gas density measurement provides important trend information about possible insulating gas losses or undesirable operating conditions, allowing preventive maintenance measures to be determined.

Continuous measurement of the insulating gas density provides valuable additional information for determining the condition of the switchgear. Switching contacts, on the other hand, protect when defined alarm values are reached and are thus safety-relevant components.

How does continuous gas density measurement according to the oscillating quartz principle work?

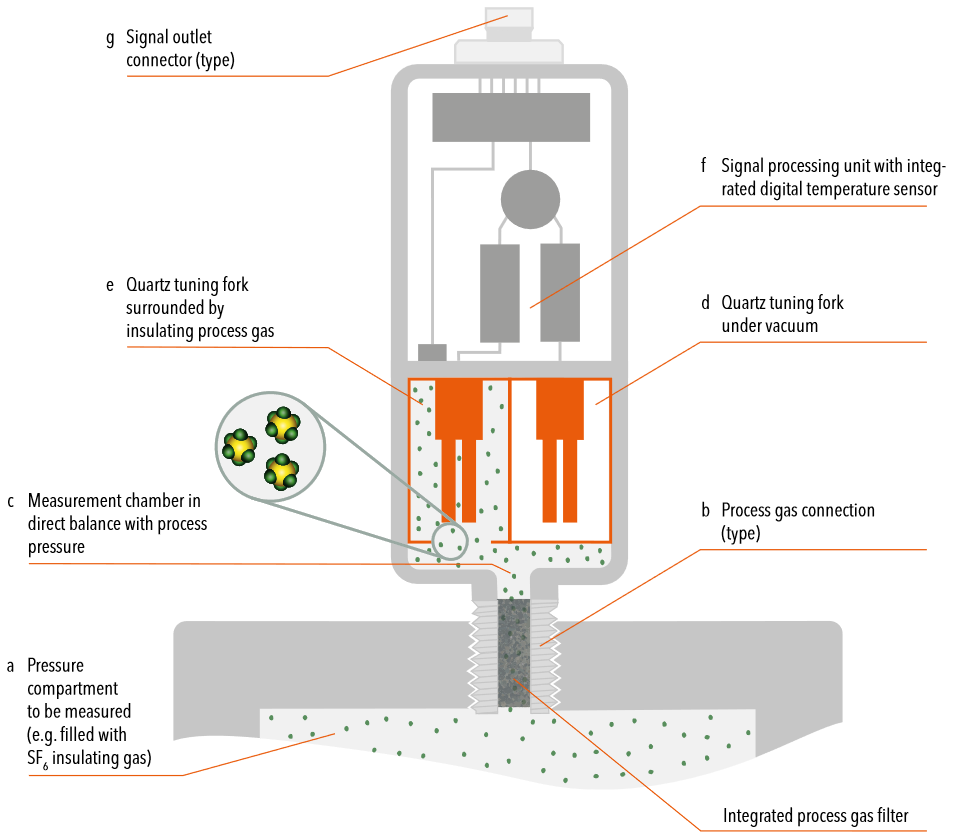

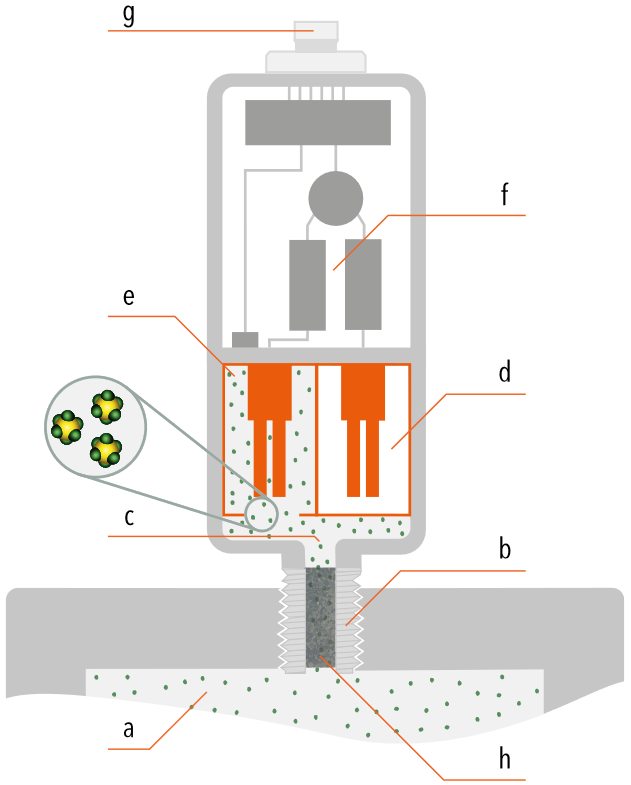

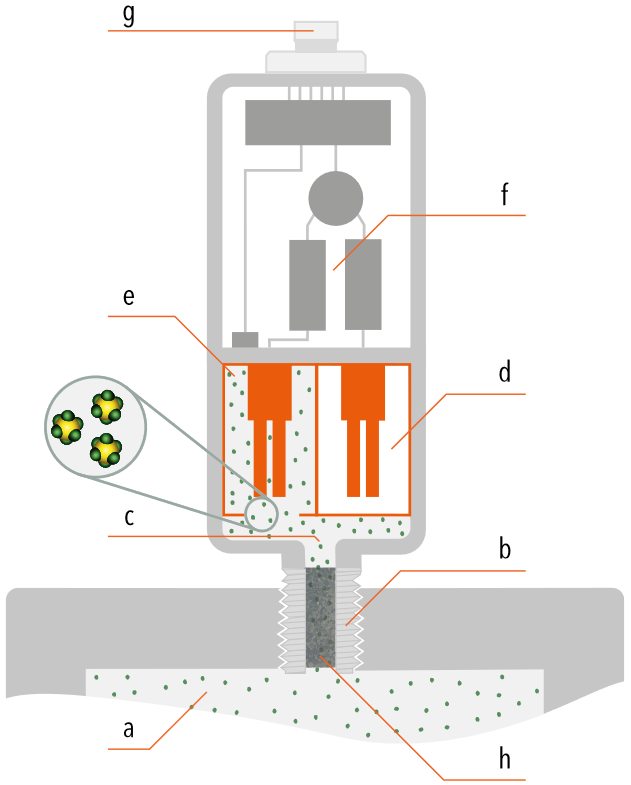

The density sensor is mounted to the pressure compartment (a) filled with insulating gas via an optionally selectable process connection (b). Thus, the density in the pressure compartment and in the sensor measuring chamber (c) is in equilibrium.

Trafag's gas density sensors are based on the comparison of the constant resonance frequency of an oscillating quartz in the vacuum (d) with the resonant frequency of an identical quartz surrounded by insualting gas (e). Gases of different density influence the preset resonance frequency of the oscillating quartz surrounded by the insulating gas.

The response time for the detection of density changes is less than 10ms. The shift of the resonance frequency is proportional to the density of the insulating gas to be measured and is evaluated by the electronics (f). The measurement signal is provided via selectable electrical output terminals (g). An analog current output signal is offered as an option.

Legend operating principle

| a Pressure compartment to be measured (e.g. filled with insulating gas SF6) b Process gas connection (type) c Measuring chamber in direct balance with the insulating gas pressure compartment d Oscillating quartz under vacuum |

e Oscillating quartz surrounded with insulating gas f Signal processing unit with integrated digital temperature sensor g Signal output connector (variant) h Integrated process gas filter |

Which measurement signals are used for continuous gas density monitoring?

The measurement signal is proportional to the density. This makes the measuring principle ideal for measuring SF6, mixed gases and all alternative gases as well as dry compressed air.

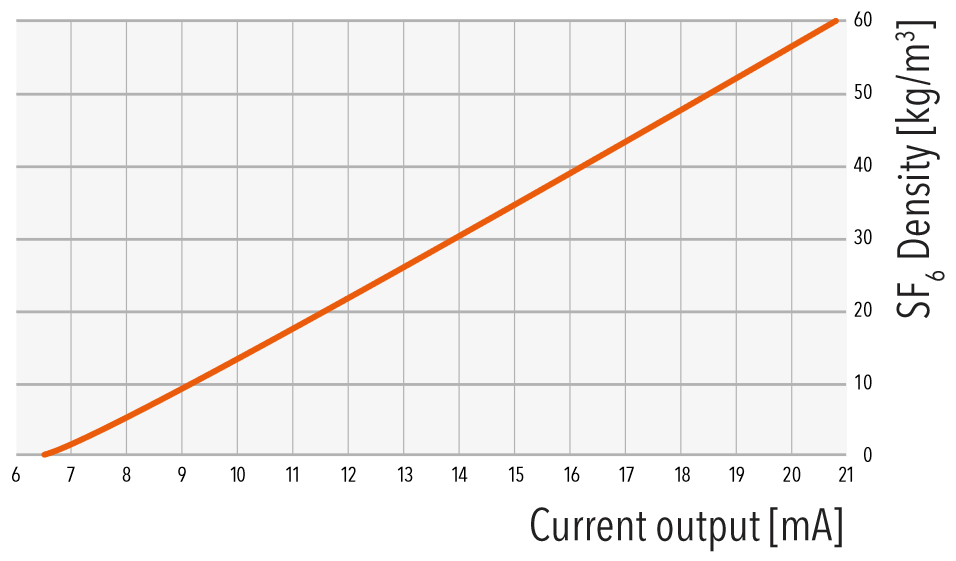

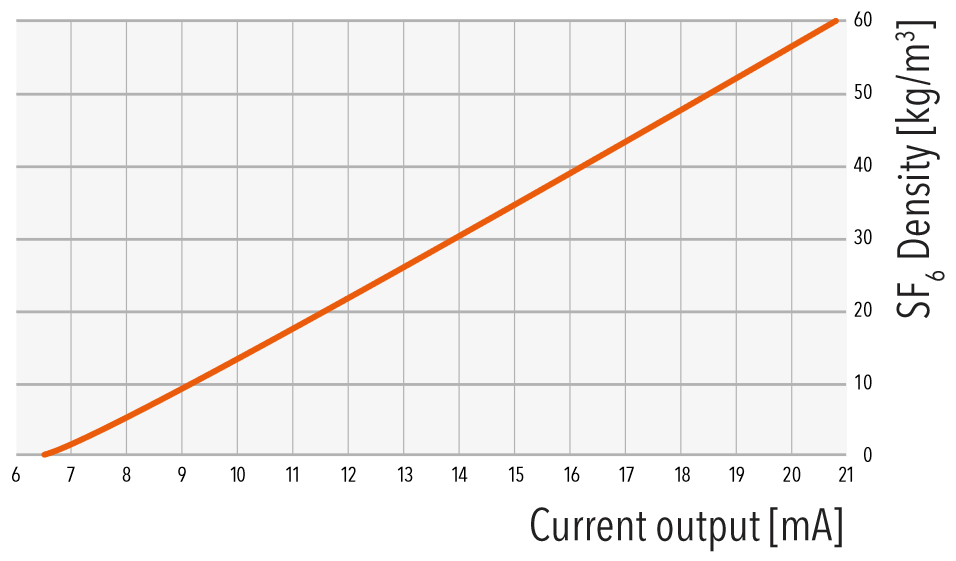

The current output signal has a resolution of 6.5 ... 20mA. Trafag provides conversion formulas for gas density and standardized gas pressure at 20 °C for SF6 and alternative insulating gases.

Example diagram: Current output signal at SF6 gas density

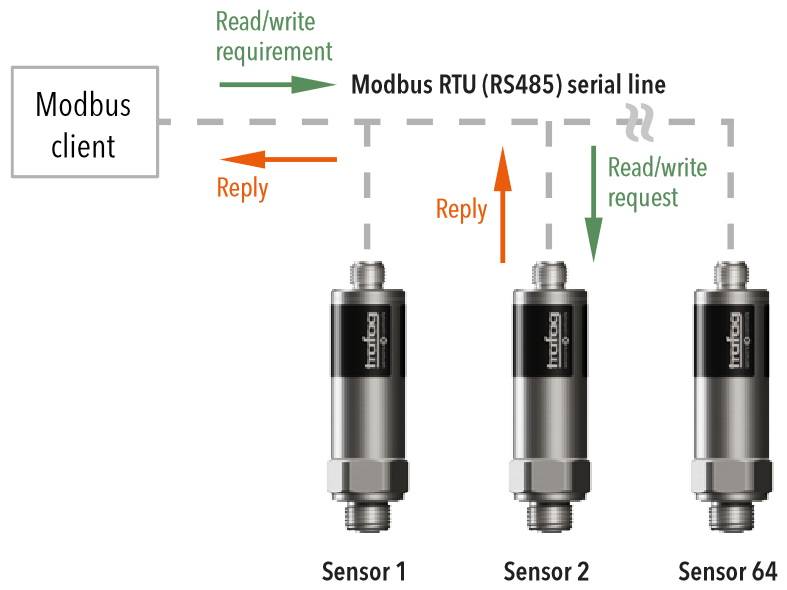

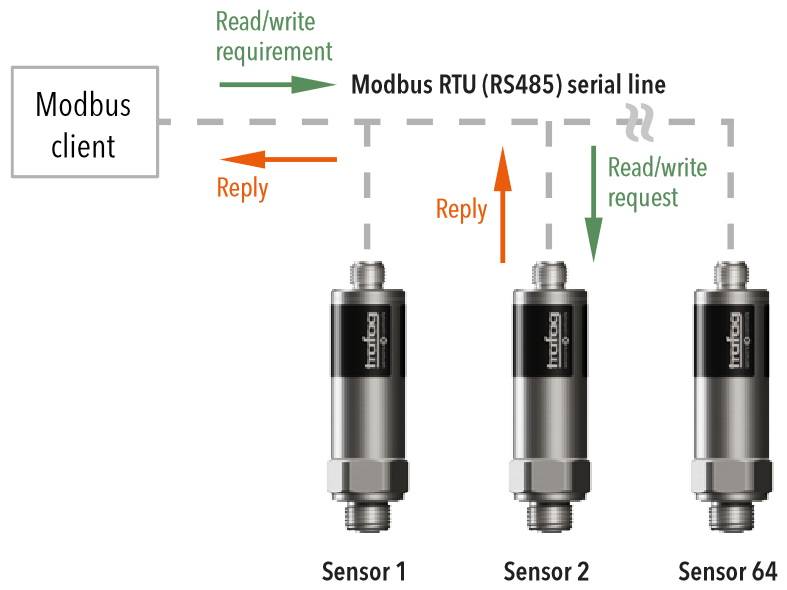

On the other hand, the signal can be transmitted via a Modbus/RS485 digital output. The evaluation electronics is additionally equipped with a temperature sensor. The temperature can be read out via the Modbus output.

The open available Modbus protocol is used for the digital data transmission between electronic devices via RS485 lines. It is a client-server protocol. In a standard Modbus network there is one client and up to 64 servers (sensors), each with a unique server address.

Gas density sensors

Electronic absolute measurement of gas density of SF6 or alternative insulating gases with patented oscillating quartz principle

The gas density sensor is based on an oscillating quartz pairing to directly measure gas density electronically - a unique technology patented by Trafag. By providing continuous output signals (analog or digital), Trafag opens up new paths for the power distribution industry. Comprehensive density trend analyses of pressure compartments are thus easy to implement. State-of-the-art production facilities under clean room conditions and strictly monitored production processes ensure that Trafag products meet the highest quality standards.

- Type 8774 with current interfaces or pulse width modulation output

- Type 8775 with digital RS485/Modbus output

Hybrid gas density monitors

Combined, mechanical monitoring and electronic measurement of the density of SF6 and alternative insulating gases

The hybrid gas density monitor combines the advantages of the mechanical monitor and the electronic gas density sensor in one compact multi-function device. With its continuous measurement output, it is ideal for use in gas management and trending systems, but also features a local display and robust switchpoint alarm contacts.

- Type 878x with current output

- Type 879x with digital RS485/Modbus output