Electronic absolute gas density measurement with quartz tuning fork

Trafag introduced the quartz tuning fork density measurement technology in the mid 1990s. It is the choice where continuous and long-term drift free density measurement and data acquisition is required. The tuning fork technology is commonly known from its use as the timefrequency standard in clocks. Exposing an oscillating tuning fork to gases of different density lead to a shift and a damping of its resonance frequency. It is a direct density measurement principle.

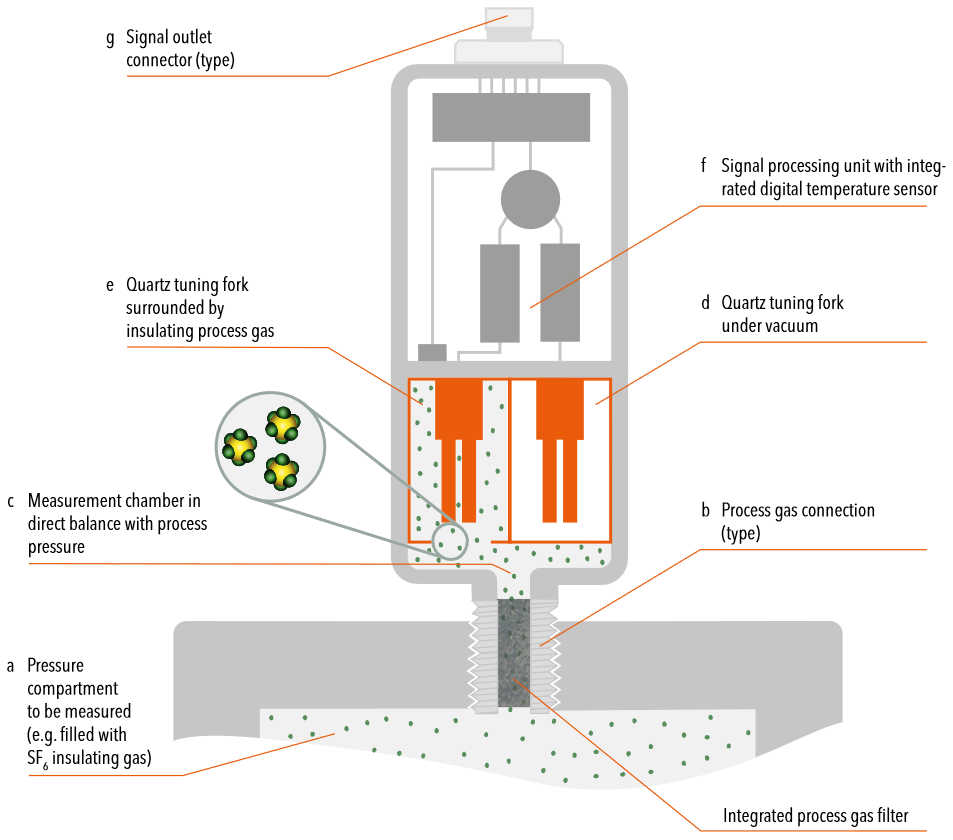

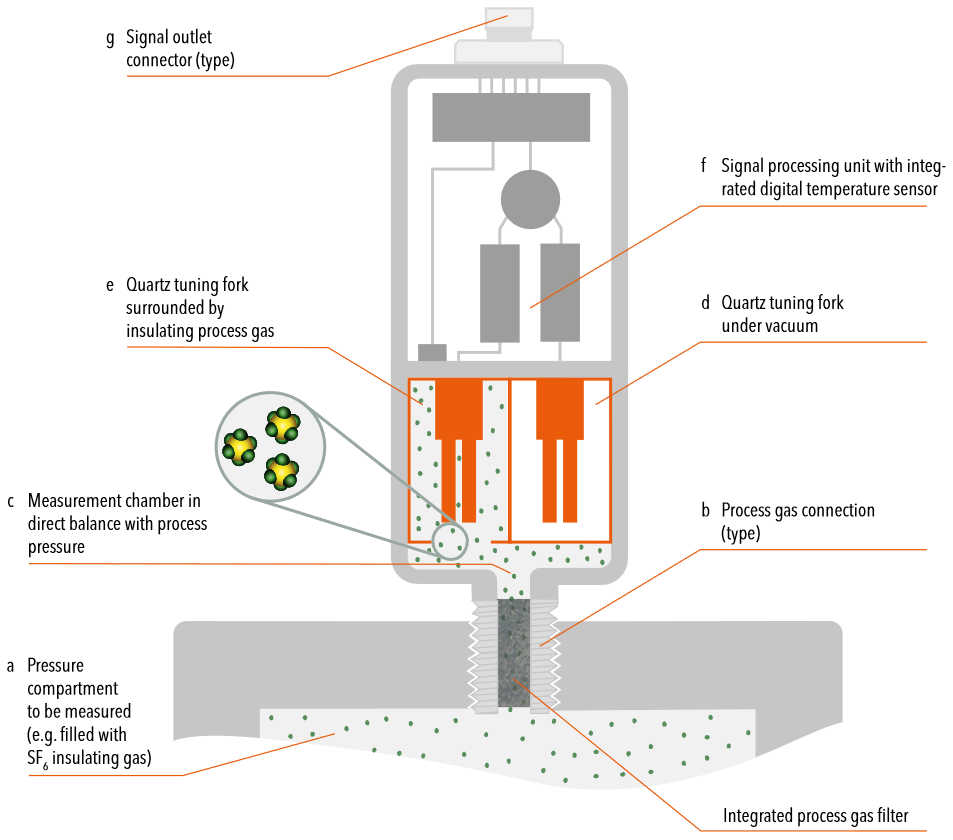

The density sensor is mounted to the pressure compartment (a) via a customizable process connection (b).

Thus, density in the insulating gas compartment and the sensor measurement chamber (c) is in balance.

Trafag density sensors use the physics by comparing the constant resonant frequency of a quartz oscillator under vacuum (d) with the resonant frequency of an identical quartz surrounded by the insulating process gas (e).

Gas of different density affects the pre-set resonant frequency of the process gas surrounded quartz tuning fork. The response time for the detection of density changes is less than 10ms.

The shift of the resonant frequency is proportional to the density of the insulating process gas. The digital processing unit features an additional temperature sensor (f). The measurement signal is provided on selectable outlet connectors (g).