Which pressure sensor is suitable for hydrogen?

With the increasing popularity of hydrogen as an energy carrier, the need for suitable pressure sensors is also increasing. While hydrogen has been used at low pressure in the chemical and process industries for years, new challenges arise in applications in H2 mobility: measuring ranges of more than 1,000bar, limited space, and increased pressure for reduced costs for large series, all require new, innovative sensor concepts.

The hydrogen molecule - as the smallest molecule of all - can penetrate the structure of many commercially available steels, and other materials, by diffusion. It can either be stored permanently in the structure, it can penetrate the structure (permeation) or there is a combination of the two effects. Hydrogen embrittlement is well known and is caused by the fact that hydrogen which has penetrated changes the structure of the steel. Permeation, i.e. the process of sorption (absorption) of hydrogen on the membrane surface, diffusion through the membrane material and desorption on the back, is not a problem in most applications, such as pressure tanks, due to the sufficiently large wall thicknesses. However, in the case of pressure sensors with the inherently thin wall thickness of the sensors, the permeation of hydrogen through the measuring membrane can lead to a reaction with elements of the sensor.

Depending on the structure and physical operating principle of the sensor, different effects can come into play. In the following sections, the most important effects are explained for those sensors regularly employed when hydrogen is used as an energy carrier. It is also shown which technical solutions are used to counteract (the harmful effects of) hydrogen permeation and what advantages and disadvantages arise from this. Finally, the most important selection criteria for a suitable pressure sensor are shown, as well as what to look out for during evaluation and qualification.

In industrial hydrogen applications, either piezoresistive sensors or thin-film-on-steel sensors (see box with the operating principles) are used almost exclusively. Other sensor principles are either technically unsuitable (e.g. ceramic sensors due to the high porosity of the sintered material), too expensive or purely niche products.

Piezoresistive sensors

With piezoresistive sensors, the extraordinarily small wall thickness of the separating membrane of only approx. 70 micrometres is a major challenge. The separating membrane itself is made of the hydrogen-compatible AISI316L as standard and therefore risk of embrittlement is minimal. However, at higher pressures, hydrogen can diffuse through the thin separating membrane into the oil filling. Hydrogen dissolved in the oil can form bubbles resulting in a sudden and strong signal offset, which can disappear again spontaneously depending on the pressure curve as soon as the bubble dissolves again.

As a countermeasure, the separating membrane is provided with a gold coating on the hydrogen side, which acts as a sorption barrier. Tests by Trafag show that this gold layer must have a certain minimum thickness in order to be able to act as a protection. The protective effect is reduced if it is too thin, if it is damaged by micro-scratches, or if the gold layer has insufficient adhesion causing the formation of small bubbles due to impurities in the plating process.

Thin-film-on-steel sensors

Thin-film-on-steel sensors, on the other hand, have a significantly thicker membrane. However, it is usually made of a material unsuitable for hydrogen (17-4PH or 1.4542), i.e. a martensitic high-performance steel with a rather low nickel content. Austenitic steels with a nickel content of more than approx. 13 percent are considered hydrogen-compatible. Therefore, alternative steel alloys must be used. Due to the principle, a high yield point is required so that the membrane and thus the sputtered resistance bridges can stretch so much that a usable signal is generated. Unfortunately, many H2-compatible steels such as AISI316L do not meet this requirement. If steel sensors with AISI316L membranes are used, they are usually not equipped with the long-term stable sputtered resistance bridge, but have a coating that shows a greater change in resistance with the same strain that is often more susceptible to signal drift.

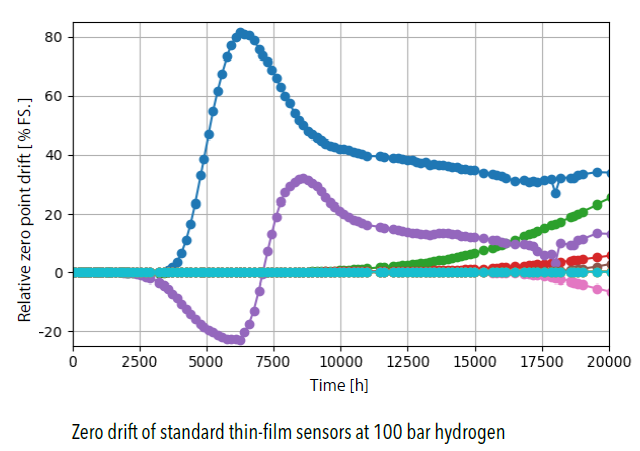

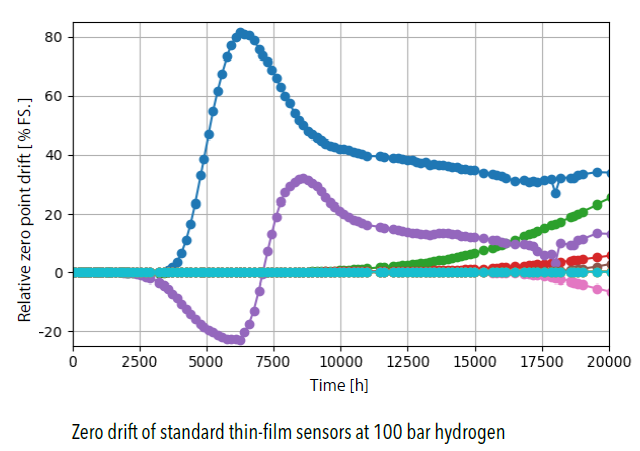

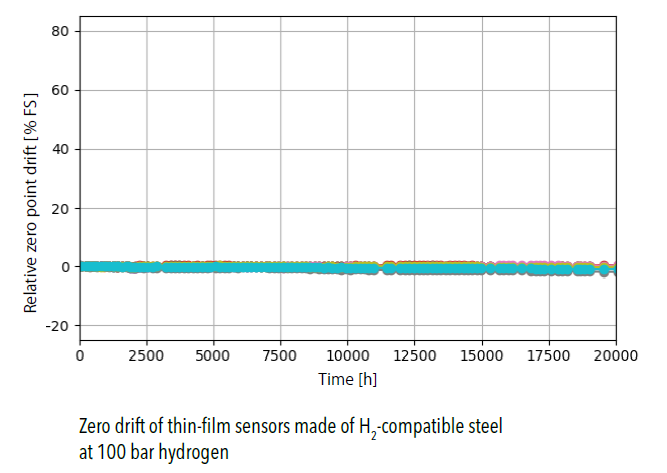

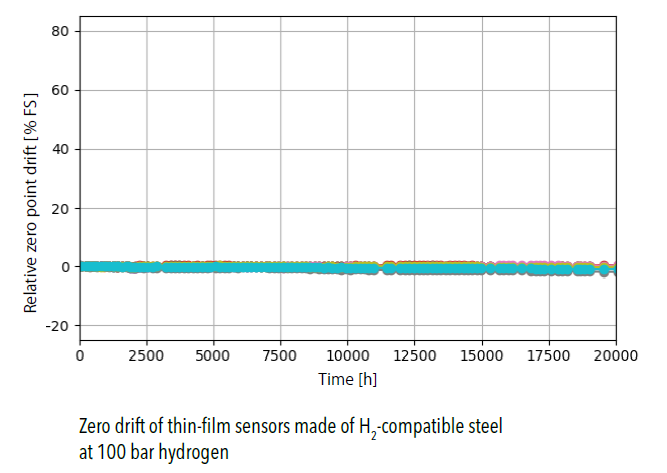

A major challenge is to find suitable steel alloys that are H2-compatible and at the same time suitable for the construction of thin-film sensors. For thin-film-on-steel cells with sputtered resistors, there are some austenitic steel alloys with a high nickel content that also have a sufficient yield point and are therefore fundamentally suitable. But for the sensor manufacturer, the difficulty with these steels is to get them from a manufacturer with the material quality that allows long-term stable, low-drift sensors to be made from it. Critical parameters are usually the homogeneity of structure, alloy and thermal treatment. Tests by Trafag with its own sensors made of various alloys and sensors from competitors have shown that many of the solutions offered today have significantly more long-term drift than conventional sensors for air or oil. Thanks to extensive experience, many years of intensive research and countless tests, Trafag has succeeded in developing a thin-film-on-steel sensor made of hydrogen-compatible steel, the long-term stability of which is significantly better than that of most of its competitors.

Long-term stability performance criterion

The long-term stability of hydrogen pressure sensors is now the main criterion when evaluating pressure transmitters. Because the design and size, electronics and mechanical structure are mostly taken from proven industrial pressure sensors, they almost always meet the requirements of hydrogen applications. The long-term stability of the sensor, i.e. that the measurement accuracy does not change, or changes only slightly over the period of use, is critical in hydrogen applications in particular. Poor long-term stability is primarily reflected in the zero point drift, which means that the signal no longer shows zero when there is no pressure. During testing, the embrittlement, which is very often mentioned in the literature as the biggest problem, did not occur with Trafag sensors. The bursting tests of the standard sensors, i.e. made of non-hydrogen-compatible material, did not show any measurable reduction in the burst pressure, even after prolonged use in a hydrogen environment, but the signals did show masive drift. In the application, three parameters in particular have a major influence on the long-term stability of hydrogen pressure sensors:

- Pressure: The higher the pressure, the stronger and faster the

diffusion effects. Alternating load cycles can also accelerate the effect because the movement of the structure facilitates the mobility of the hydrogen that has penetrated. - Temperature: The higher the temperature, the faster the harmful effect of hydrogen manifests itself. The embrittlement decreases again from about 60°C, but the diffusion continues to increase.

- Time: The duration of exposure to hydrogen is critical. The signal deviations only become apparent after a certain time and are not linear.

While the effects of pressure and temperature are obvious and are taken into account in the evaluation in the test criteria, the exposure duration is often not taken into account enough. Trafag tests have shown that sensors made of unsuitable standard membrane steel sometimes only show the characteristic zero-point drift effects after 10,000 hours of hydrogen exposure and that there is a large scatter as to when the zero-point drift actually begins.

Many of these drift effects are reversible with steel sensors: When the sensor is no longer exposed to hydrogen, the hydrogen concentration slowly decreases, even relatively quickly at higher temperatures above roughly 80°C.

Consequences for the evaluation of hydrogen pressure sensors

The qualification of suitable devices is a major challenge for the user of hydrogen pressure sensors. In addition, an incorrect pressure measurement can lead to serious consequences - including endangering human life. Meaningful tests must therefore be carried out over several thousand hours, ideally in an application-oriented test setup. Application-oriented means that above all the level of pressure, the pressure cycles and the temperature conditions best represent the worst-case conditions in the target application. In order to keep the variety of devices that have to be tested in such a complex way small, it is worthwhile to only consider providers with a lot of experience and know-how, who also carry out intensive internal qualification tests, right from the pre-selection stage.

Are you looking for reliable and robust hydrogen pressure sensors?

Contact us. Our specialists will be happy to advise you and work with you to find suitable solutions for your application.

Tel: +41 44 922 32 00

E-Mail: trafag@trafag.com

Functional principle of various pressure sensors

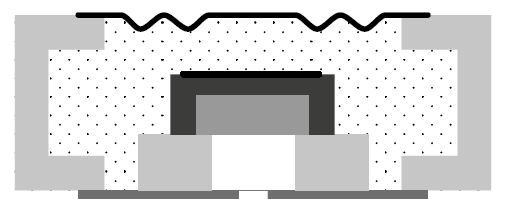

Piezoresistive pressure sensor

The pressure of the medium acts on the separating diaphragm, which transfers the pressure to the oil filling. The active layer of the semiconductor element in the oil is deformed due to the pressure. Due to the change in shape, the resistance that is measured changes. The separating membrane must be very thin so that it can transfer the pressure to the oil without distortion.

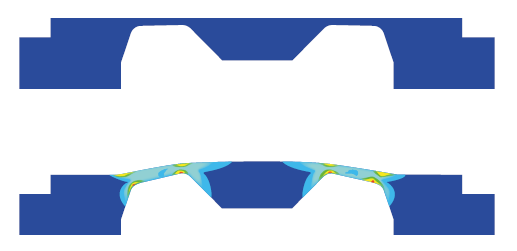

Thin-film-on-steel pressure sensor

The pressure of the medium acts on the steel membrane. This has a precisely defined rigidity and only deforms very locally due to its special shape. Resistors are applied to the side facing away from the medium at the points with maximum deformation. Depending on the position, the resistances are compressed or stretched, which leads to an increase or decrease in resistance. The sum of the absolute changes in resistance is measured using a Wheatstone bridge.

Suitable pressure transmitters for hydrogen

Do you have questions about our pressure transmitters?

We'd be glad to help. Please get in touch with us.