Components of a pressure transmitter

A pressure transmitter measures the physical quantity of pressure in liquids or gases and provides the measured value as an electrical signal. The interactive graphic on this page guides you to the most important information about the key elements of a pressure transmitter: In addition to the main functional design elements, these are the interfaces to the environment, the most important criteria for selecting a proper pressure transmitter and the most important performance characteristics. The core elements of a pressure transmitter are the measuring cell, i.e. the sensor in the closer sense, the process connection; the electronics for signal processing; the electrical connection as well as the enclosing housing.

Trafag pressure sensors are mainly based either on thin-film-on-steel technology with a welded sensor made of stainless steel and without an O-ring or on thick-film-on-ceramic technology. Both sensor technologies originate from Trafag's own in-house production and were developed together with the ASIC (application-specific microchip).

As a result, the pressure sensor and electronics are perfectly matched and achieve their unique long-term stability and reliability even under the most adverse environmental conditions in demanding applications.

Interfaces of a pressure transmitter

The most important interfaces to the outside are the process connection, i.e., the pressure connection side, and the electrical connection, also called the signal connection. In industrial applications, these interfaces are standardised. Depending on the industry and application, different interfaces are used. Today's pressure transmitters are available with a variety of process connections, output signals and electrical connections. Industrial sensors with different technologies enable measurement from a few mbar up to several thousand bar, with an accuracy of up to 0.1%. From the electrical connection, which usually consists of a plug or a connection cable, the measured value output is either an analogue signal or a digital signal. The most common analogue output signals are 4 ... 20mA and 0 ... 10VDC.

The advantage of digital signals is the bidirectional communication, which enables diagnosis as well as easy configuration of the pressure measurement (e.g. change of the pressure measuring unit from bar to psi).

On the other hand, other physical measured variables can be provided in addition to pressure, such as temperature. In addition to electronic pressure transmitters with analogue and digital output signals, there are also electronic pressure switches. These do not output a measured value but have one or more transistor outputs or relay outputs.

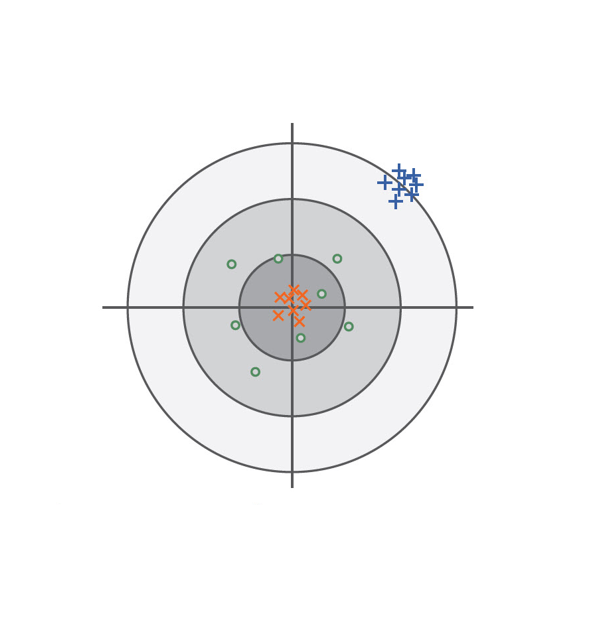

Performance features of a pressure transmitter

In addition to the pressure connection and the electrical connection, other criteria are central to the selection of a suitable pressure transmitter: The most important performance features for selecting a pressure transmitter are the measuring range, the required type of measurement (absolute, relative, or differential pressure) and the desired accuracy.

Depending on the area of application, compliance with certain standards and directives must be considered, such as railway standards, explosion protection standards or ship approvals. In addition, environmental influences must be taken into account: Vibrations, shock, water and dust, electromagnetic interference, ambient temperature, the temperature of the measured medium. When selecting the material, it is important that the parts in contact with the medium are chosen in such a way that the material cannot be corroded by the medium.

This is because corrosion of measuring cells and process connections, occasionally also of housings and the electronics, are frequent causes of failure of pressure transmitters.

Another cause of defective pressure transmitters are very high pressure peaks, as they occur especially in liquids. These pressure peaks, which often last only milliseconds, can be several times the normal measuring range and thus destroy the sensitive diaphragm of the pressure transducer. Apart from special damping elements, which act like an aperture in the process connection, the only solution in such cases is often the selection of a pressure transmitter type with particularly high overpressure safety.

In our know-how section you will find further information on the above-mentioned aspects:

-

NAI 8273Out of stock

NAI 8273Out of stock -

FPI 8237Out of stock

FPI 8237Out of stock -

NHT 8250Out of stock

NHT 8250Out of stock -

FPT 8236Out of stock

FPT 8236Out of stock -

NAE 8256Out of stock

NAE 8256Out of stock -

CMP 8271Out of stock

CMP 8271Out of stock -

EXNT 8292Out of stock

EXNT 8292Out of stock -

EXNAL 8858Out of stock

EXNAL 8858Out of stock -

EXNA 8854Out of stock

EXNA 8854Out of stock -

EXNA 8852/8853Out of stock

EXNA 8852/8853Out of stock -

ESH 8845Out of stock

ESH 8845Out of stock -

EXNAL 8859Out of stock

EXNAL 8859Out of stock -

NAL 8838Out of stock

NAL 8838Out of stock -

ECR 8478Out of stock

ECR 8478Out of stock -

ECTN 8477Out of stock

ECTN 8477Out of stock -

ECT 8473Out of stock

ECT 8473Out of stock -

ECT 8472Out of stock

ECT 8472Out of stock -

ECL 8439Out of stock

ECL 8439Out of stock -

DPS 8381Out of stock

DPS 8381Out of stock -

DPC 8380Out of stock

DPC 8380Out of stock -

EPN-S 8320Out of stock

EPN-S 8320Out of stock -

EPN/EPNCR 8298Out of stock

EPN/EPNCR 8298Out of stock -

EPR 8293Out of stock

EPR 8293Out of stock -

EPN 8288Out of stock

EPN 8288Out of stock -

EPI 8287Out of stock

EPI 8287Out of stock -

EPR 8283Out of stock

EPR 8283Out of stock -

NPN 8264Out of stock

NPN 8264Out of stock -

NAR 8258Out of stock

NAR 8258Out of stock -

NAR 8258Out of stock

NAR 8258Out of stock -

NSL 8257Out of stock

NSL 8257Out of stock -

NAE 8256Out of stock

NAE 8256Out of stock -

NAH 8254 20 kHzOut of stock

NAH 8254 20 kHzOut of stock -

NAH 8254Out of stock

NAH 8254Out of stock -

NAH 8254Out of stock

NAH 8254Out of stock -

NAH 8253Out of stock

NAH 8253Out of stock -

NAT 8252Out of stock

NAT 8252Out of stock -

NAT 8252Out of stock

NAT 8252Out of stock -

H 8212/8213Out of stock

H 8212/8213Out of stock -

ND 8204Out of stock

ND 8204Out of stock -

N 8202Out of stock

N 8202Out of stock -

NAP 8842/8843Out of stock

NAP 8842/8843Out of stock