Countermeasures against aggressive SF6 by-products

SF6 is inert during normal use. When electrical discharges occur within SF6 filled gas compartments, mechanical abrasion, toxic and material-aggressive by-products can emerge. The two main by-products that may occur are hydrofluoric acid and thionyl fluoride. Both can cause long-term damage to improper material selection. Abrasion particles can cause sensing element degradation. Trafag deals with it by using suitable materials and additional integrated process gas filters.

Materials for process gas connection, reference gas chamber and bellows system are specifically selected to withstand hydrofluoric acid and thionyl fluoride. High-alloyed stainless steels 1.4404, 1.4435, 1.4571 (AISI316L, AISI316Ti) are used.

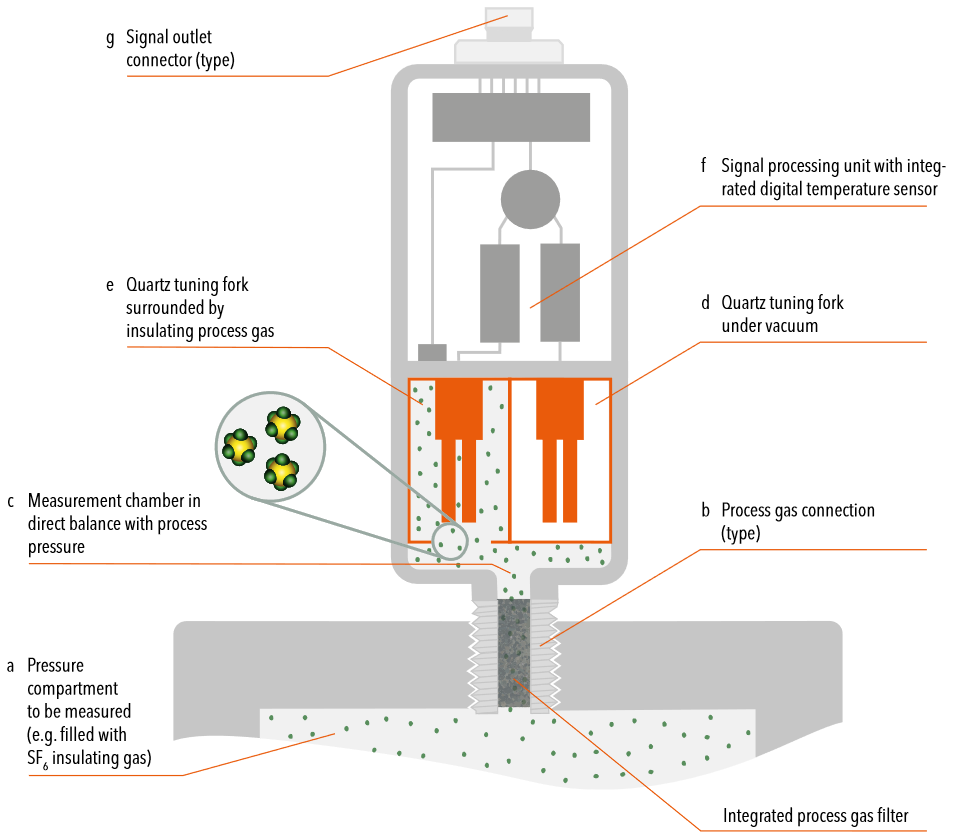

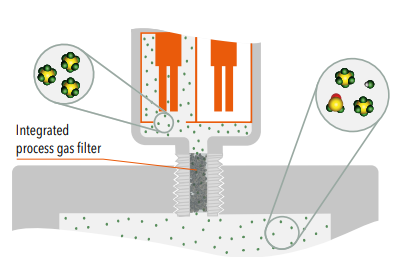

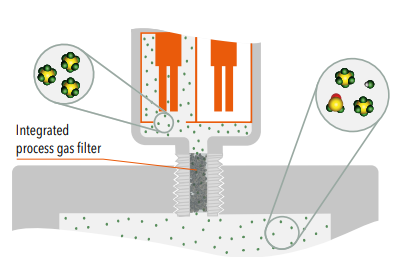

The quartz tuning fork requires advanced countermeasures to repel ingress of aggressive by-products that may occur in insulating gases. Materials for the process gas connection and measurement chamber are specifically selected. High-alloyed stainless steels 1.4404 and 1.4435 (AISI316L) are used. An additional integrated process gas filter protects from fine abrasion particles and absorbs corrosive gases.

During normal operation, insulating gas density changes are detected in less than 10 ms. The integrated filter element induces a transient response time after installation and initial insulating gas filling. Therefore, a minimised time period for gas equalization between process compartment and the sensor's measurement chamber occurs.

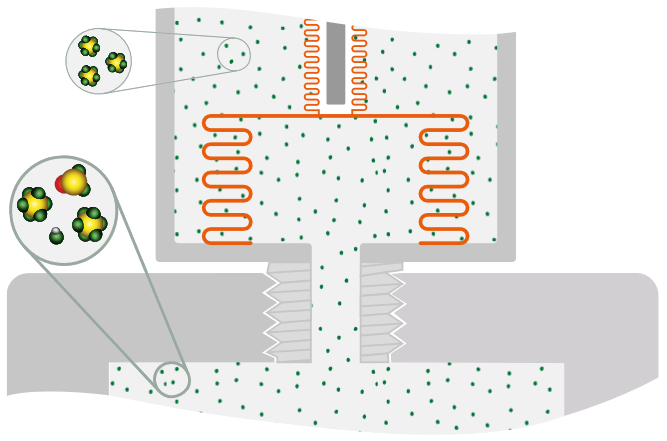

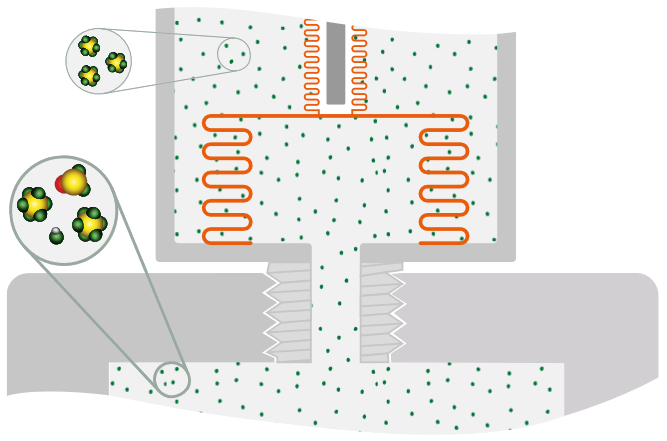

Countermeasures for devices with reference gas comparison

Materials for process gas connection, reference gas chamber and bellows system are specifically selected to withstand hydrofluoric acid and thionyl fluoride. High-alloyed stainless steels 1.4404, 1.4435, 1.4571 (AISI316L, AISI316Ti) are used.

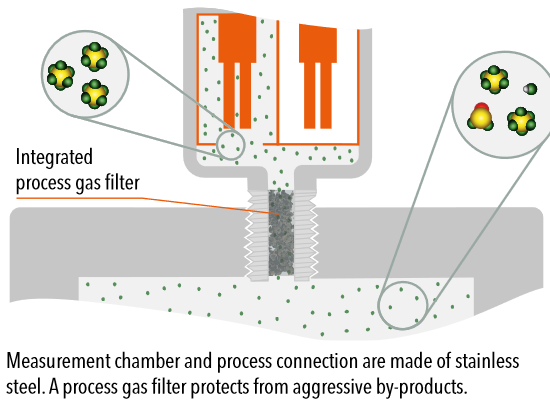

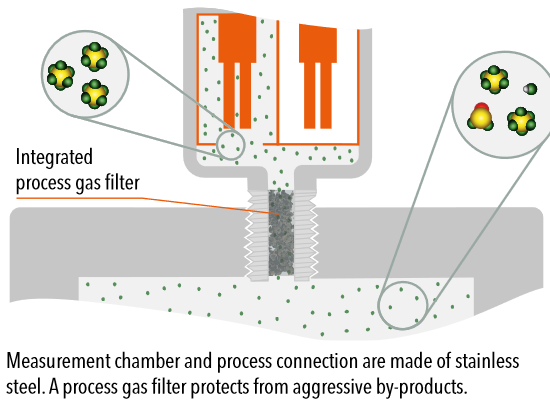

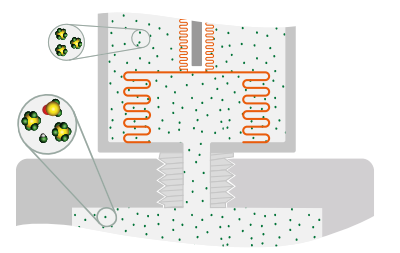

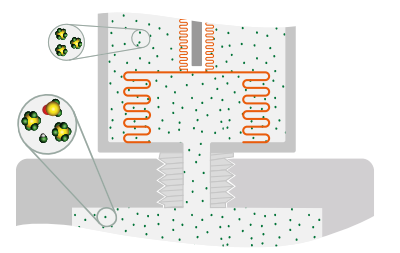

Countermeasures for devices with quartz tuning fork technology

The quartz tuning fork requires advanced countermeasures to repel ingress of aggressive by-products that may occur in insulating gases. Materials for the process gas connection and measurement chamber are specifically selected. High-alloyed stainless steels 1.4404 and 1.4435 (AISI316L) are used. An additional integrated process gas filter protects from fine abrasion particles and absorbs corrosive gases.

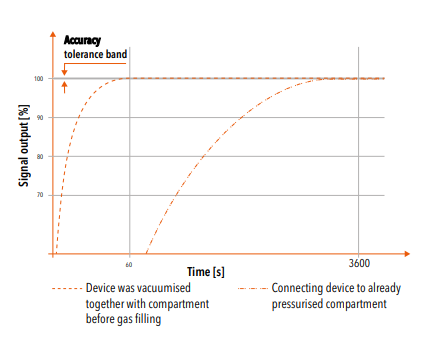

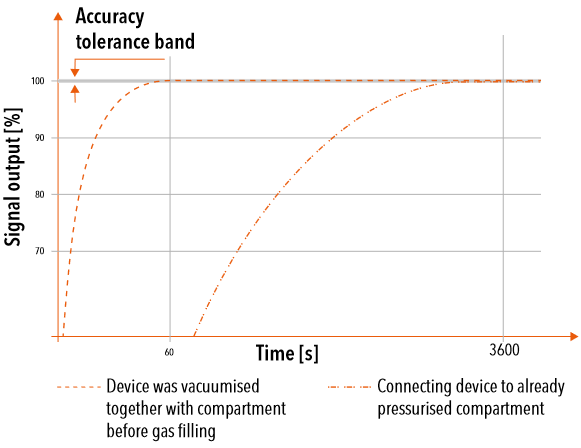

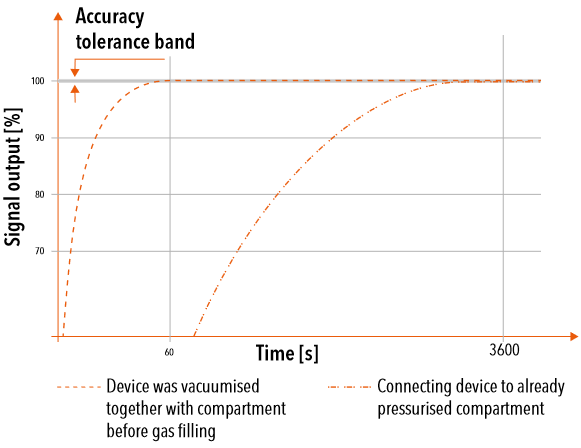

Response time of the integrated process gas filter of the density sensor

During normal operation, insulating gas density changes are detected in less than 10 ms. The integrated filter element induces a transient response time after installation and initial insulating gas filling.

Therefore, a minimised time period for gas equalization between process compartment and the sensor's measurement chamber occurs.